- CNC Servo Press Brake

- WE67KM-63/2500 CNC Servo Press Brake

- WE67KS-100/2500 CNC Servo Press Brake

- WE67KM-110/2500 CNC Servo Press Brake

- WE67KM-130/3200 CNC Servo Press Brake

- WE67KM-130/4100 CNC Servo Press Brake

- WE67KS-170/3200 CNC Servo Press Brake

- WE67KS-170/4100 CNC Servo Press Brake

- WE67KS-200/2500 CNC Servo Press Brake

- WE67KM-200/5000 CNC Servo Press Brake

- WE67KS-250/4000 CNC Servo Press Brake

- WE67KM-800/9000 CNC Servo Press Brake

- CNC Press Brake

- WC67K-40/1200 CNC Press Brake

- WE67K-63/2500 CNC Press Brake

- WE67K-80/2500 CNC Press Brake

- WE67K-100/3200 CNC Press Brake

- WE67K-100/4000 CNC Press Brake

- WE67K-125/2500 CNC Press Brake

- WE67K-125/3200 CNC Press Brake

- WE67K-125/4000 CNC Press Brake

- WE67K-160/3200 CNC Press Brake

- WE67K-160/4000 CNC Press Brake

- WE67K-160/5000 CNC Press Brake

- WE67K-160/6000 CNC Press Brake

- WE67K-200/2500 CNC Press Brake

- WE67K-200/3200 Servo CNC Press Brake

- WE67K-200/4000 CNC Press Brake

- WE67K-200/6300 CNC Press Brake

- WE67K-250/3200 CNC Press Brake

- WE67K-250/4000 CNC Press Brake

- WE67K-250/5000 CNC Press Brake

- WE67K-250/6000 CNC Press Brake

- WE67K-300/3200 CNC Press Brake

- WE67K-300/4000 CNC Press Brake

- WE67K-300/6000 CNC Press Brake

- WE67K-400/3200 CNC Press Brake

- WE67K-400/4000 CNC Press Brake

- WE67K-400/5000 CNC Press Brake

- WE67K-400/6000 CNC Press Brake

- WE67K-400/6300 CNC Press Brake

- WE67K-500/6000 CNC Press Brake

- WE67K-600/4000 CNC Press Brake

- WE67K-600/5000 CNC Press Brake

- WE67K-600/6000 CNC Press Brake

- WE67K-600/7000 CNC Press Brake

- WE67K-800/6000 CNC Press Brake

- WE67K-800/7000 CNC Press Brake

- WE67K-800/8000 CNC Press Brake

- WE67K-800/9000 CNC Press Brake

- WE67K-1000/6000 CNC Press Brake

- WE67K-1000/7000 CNC Press Brake

- WE67K-1000/10000 CNC Press Brake

- WE67K-1200/5000 CNC Press Brake

- WE67K-1200/8000 CNC Press Brake

- WE67K-1200/9000 CNC Press Brake

- WE67K-1200/12000 CNC Press Brake

- WE67K-1600/12000 CNC Press Brake

- WE67K-2000/10000 CNC Press Brake

- WE67K-2000/12000 CNC Press Brake

- WE67K-2500/11000 CNC Press Brake

- WE67K-2500/12000 CNC Press Brake

- WE67K-3000/14000 CNC Press Brake

- WE67K-4000/14000 CNC Press Brake for construction Machinery

- 4 Rollers Plate Bending

- W12NC-4x1500 Four Rollers Plate Bending Machine

- W12NC-4x3000 Plate Bending Machine

- W12NC-5x800 Four Rollers Plate Bending Machine

- W12NC-6x2000 Plate Bending Machine

- W12NC-6x2500 Plate Bending Machine

- W12NC-6x3000 Plate Bending Machine

- W12NC-8x1500 Four Rollers Plate Bending Machine

- W12NC-8x2000 Plate Bending Machine

- W12NC-8x2500 Plate Bending Machine

- W12NC-8x3000 Plate Bending Machine

- W12NC-10x1500 Plate Bending Machine

- W12NC-10x2500 Plate Bending Machine

- W12NC-10x3000 4 Rollers Plate Bending Machine

- W12NC-10x5000 4 Rollers Plate Bending Machine

- W12NC-12x1500 4 Rollers Plate Bending Machine

- W12NC-12X2500 Plate Bending Machine

- W12NC-12x3000 Plate Bending Machine

- W12NC-12x6000 Plate Bending Machine

- W12NC-16x2000 Plate Bending Machine

- W12NC-16x2500 Plate Bending Machine

- W12NC-16x3000 Plate Bending Machine

- W12NC-20x800 Plate Bending Machine

- W12NC-20x1000 Plate Bending Machine

- W12NC-20x2000 Plate Bending Machine

- W12NC-20x2500 Plate Bending Machine

- W12NC-20x3000 Plate Bending Machine

- W12NC-20x4000 Plate Bending Machine

- W12NC-25x1500 Plate Bending Machine

- W12NC-25x2500 Plate Bending Machine

- W12NC-25x3000 Plate Bending Machine

- W12NC-25x3200 Plate Bending Machine

- W12NC-30x2500 Plate Bending Machine

- W12NC-30x3000 Plate Bending Machine

- W12NC-35x2500 Plate Bendign Machine

- W12NC-40x2500 4 Rollers Plate Bending Machine

- W12NC-40x3000 4 Roller Plate Bending Machine

- W12NC-50x2500 4 Rollers Plate Bending Machine

- W12NC-50x3000 4 Rollers Plate Bending Machine

- W12NC-60x2500 4 Rollers Plate Bending Machine

- W12NC-60x3000 4 Rollers Plate Bending Machine

- W12NC-70x3000 4 Rollers Plate Bending Machine

- W12NC-80x3000 4 Rollers Plate Bending Machine

- W12NC-120x3000 four rollers plate bending machine

- CNC Torsion Press Brake

- WH67K-100/2500 Torsion CNC Press Brake

- WH67K-100/3200 Torsion CNC Press Brake

- WH67K-125/2500 Torsion CNC Press Brake

- WH67K-125/3200 Torsion CNC Press Brake

- WH67K-125/4000 Torsion CNC Press Brake

- WH67K-160/3200 Torsion CNC Press Brake

- WH67K-160/4000 Torsion CNC Press Brake

- WH67K-160/6300 Torsion CNC Press Brake

- WH67K-200/3200 Torsion CNC Press Brake

- WH67K-200/4000 Torsion CNC Press Brake

- WH67K-250/4000 Torsion CNC Press Brake

- WH67K-300/4000 Torsion CNC Press Brake

- NC Press Brake

- WE67Y-63/2500 Hydraulic Press Brake

- WE67Y-100/2500 Hydraulic Press Brake

- WE67Y-100/3200 Hydraulic Press Brake

- WE67Y-100/4000 Hydraulic Press Brake

- WE67Y-125/2500 Hydraulic Press Brake

- WE67Y-125/4000 Hydraulic Press Brake

- WE67Y-125/6300 Hydraulic Press Brake

- WE67Y-160/3200 Hydraulic Press Brake

- WE67Y-160/4000 Hydraulic Press Brake

- WE67Y-160/6000 Hydraulic Press Brake

- WE67Y-200/3200 Hydraulic Press Brake

- WE67Y-200/4000 Hydraulic Press Brake

- WE67Y-200/6000 Hydraulic Press Brake

- WE67Y-250/3200 Hydraulic Press Brake

- WE67Y-250/4000 Hydraulic Press Brake

- WE67Y-300/3200 Hydraulic Press Brake

- WE67Y-300/4000 Hydraulic Press Brake

- WE67Y-300/6000 Hydraulic Press Brake

- WE67Y-400/3200 Hydraulic Press Brake

- WE67Y-400/4000 Hydraulic Press Brake

- WE67Y-400/5000 Hydraulic Press Brake

- WE67Y-400/6000 Hydraulic Press Brake

- WE67Y-600/6000 Hydraulic Press Brake

- Press Brake in Tandem

- 2xWE67K-160/4000 CNC Press Brake in Tandem

- 2xWE67K-200/6300 CNC Press Brake in Tandem

- 2xWE67K-300/4000 CNC Press Brake in Tandem

- 2xWE67K-400/4000 CNC Press Brake in Tandem

- 2xWE67K-400/5000 CNC Press Brake in Tandem

- 2xWE67K-400/7000 CNC Press Brake in Tandem

- 2xWE67K-500/4100 CNC Press Brake in Tandem

- 2xWE67K-500/6000 CNC Press Brake in Tandem

- 2xWE67K-600/6000 CNC Press Brake in Tandem

- 2xWE67K-800/6000 CNC Press Brake in Tandem

- 2xWE67K-800/7000 CNC Press Brake in Tandem

- WE67K-800/8000+WE67K-400/4000 CNC Press Brake in Tandem

- 2xWE67K-1000/6000 CNC Press Brake in Tandem

- 2xWE67K-1200/7000 CNC Press Brake in Tandem

- 2xWE67K-1200/8000 CNC Press Brake in Tandem

- 2xWE67K-500/4100 CNC Press Brake in Tandem

- 2xWE67K-1600/6000+WE67K-800/6000 CNC Press Brake in Tandem

- 2xWE67K-1600/6000 CNC Press Brake in Tandem

- 2xWE67K-1600/7000 CNC Press Brake in Tandem

- Cute Press Brake

- WC67Y-30/1300 Press Brake

- WC67Y-30/1600 Press Brake

- WC67Y-40/1300 Press Brake

- WC67Y-40/1600 Press Brake

- WC67Y-40/2000 Press Brake

- WC67Y-40/2500 Press Brake

- WC67Y-63/1600 Press Brake

- WC67Y-63/2000 Press Brake

- WC67Y-63/2500 Hydraulic Press Brake

- WC67Y-63/2500 Hydraulic Press Brake

- WC67Y-80/2000 Hydraulic Press Brake

- WC67Y-80/2500 Press Brake

- WC67Y-80/3200 Small Press Brake

- Guillotine Shearing Machine

- QC11Y-6x2500 Hydraulic Guillotine Shearing Machine

- QC11Y-6x3200 Hydraulic Guillotine Shearing Machine

- QC11Y-6x4000 Hydraulic Guillotine Shearing Machine

- QC11Y-6x6000 Hydraulic Guillotine Shearing Machine

- QC11Y-8x2500 Hydraulic Guillotine Shearing Machine

- QC11Y-8x3200 Hydraulic Guillotine Shearing Machine

- QC11Y-8x6000 Hydraulic Guillotine Shearing Machine

- QC11Y-10x2500 Hydraulic Guillotine Shearing Machine

- QC11Y-10x3200 Hydraulic Guillotine Shearing Machine

- QC11Y-10x4000 Hydraulic Guillotine Shearing Machine

- QC11Y-12x2500 Hydraulic Guillotine Shearing Machine

- QC11Y-12x3200 Hydraulic Guillotine Shearing Machine

- QC11Y-12x4000 Hydraulic Guillotine Shearing Machine

- QC11Y-12x6000 Hydraulic Guillotine Shearing Machine

- QC11Y-12x8000 Hydraulic Guillotine Shearing Machine

- QC11Y-12x9000 Hydraulic Guillotine Shearing Machine

- QC11Y-16x2500 Hydraulic Guillotine Shearing Machine

- QC11Y-16x3200 Hydraulic Guillotine Shearing Machine

- QC11Y-16x4000 Hydraulic Guillotine Shearing Machine

- QC11Y-20x2500 Hydraulic Guillotine Shearing Machine

- QC11Y-20x3200 Hydraulic Guillotine Shearing Machine

- QC11Y-16x6000 Hydraulic Guillotine Shearing Machine

- QC11Y-16x8000 Hydraulic Guillotine Shearing Machine

- QC11Y-16x9000 Hydraulic Guillotine Shearing Machine

- QC11Y-16x12000 Hydraulic Guillotine Shearing Machine

- QC11Y-20x6000 Hydraulic Guillotine Shearing Machine

- QC11Y-20x8000 Hydraulic Guillotine Shearing Machine

- QC11Y-20x13000 Hydraulic Guillotine Shearing Machine

- QC11Y-25x2500 Hydraulic Guillotine Shearing Machine

- QC11Y-25x3200 Hydraulic Guillotine Shearing Machine

- QC11Y-25x6000 Hydraulic Guillotine Shearing Machine

- QC11Y-25x10000 Hydraulic Guillotine Shearing Machine

- QC11Y-30x2500 Hydraulic Guillotine Shearing Machine

- QC11Y-30x6000 Hydraulic Guillotine Shearing Machine

- QC11Y-40x2500 Hydraulic Guillotine Shearing Machine

- QC11Y-40x3200 Hydraulic Guillotine Shearing machine

- CNC Shearing Machine

- QC11K-6x5000 CNC Guillotine Shearing Machine

- QC11K-8x2500 CNC Guillotine Shearing Machine

- QC11K-12x4000 CNC Guillotine Shearing Machine

- QC11K-16x3200 CNC Guillotine Shearing Machine

- QC11K-16x6300 CNC Guillotine Shearing Machine

- QC11K-20x6200 CNC Guillotine Shearing Machine

- QC11K-25x2500 CNC Shearing Machine

- QC11K-30x6200 CNC Shearing Machine

- QC11K-30x9000 CNC shearing machine

- Swing Beam Shearing Machine

- QC12Y-4x1600 hydraulic swing beam shearing machine

- QC12Y-6x1500 hydraulic swing beam shearing machine

- QC12Y-4x2500 hydraulic swing beam shearing machine

- QC12Y-4x3200 hydraulic swing beam shearing machine

- QC12Y-6x2500 hydraulic swing beam shearing machine

- QC12Y-6x3200 hydraulic swing beam shearing machine

- QC12Y-8x2500 hydraulic swing beam shearing machine

- QC12Y-8x3200 hydraulic swing beam shearing machine

- QC12Y-10x2500 hydraulic swing beam shearing machine

- QC12Y-10x3200 hydraulic swing beam shearing machine

- QC12Y-10x4000 hydraulic swing beam shearing machine

- QC12Y-12x2500 hydraulic swing beam shearing machine

- QC12Y-12x3200 hydraulic swing beam shearing machine

- Universal Plate Bending Machine

- W11SNC-6x2500 Plate Bending Machine

- W11SNC-10x2500 Plate Bending Machine

- W11SNC-12x1500 Plate Bending Machine

- W11SNC-12x2000 Plate Bending Machine

- W11SNC-12x2500 Plate Bending Machine

- W11SNC-12x3000 Plate Bending Machine

- W11SNC-16x2500 Plate Bending Machine

- W11SNC-16x3000 Plate Bending Machine

- W11SNC-20x2500 Plate Bending Machine

- W11SNC-20x3000 Plate Bending Machine

- W11SNC-25x2500 Plate Bending Machine

- W11SNC-25x3000 Plate Bending Machine

- W11SNC-30x2500 Plate Bending Machine

- W11SNC-30x3000 Plate Bending Machine

- W11SNC-35x2500 Plate Bending Machine

- W11SNC-35x3000 Plate Bending Machine

- W11SNC-40x2500 Plate Bending Machine

- W11SNC-40x3000 Plate Bending Machine

- W11SNC-50x2500 Plate Bending Machine

- W11SNC-50x3000 Plate Bending Machine

- W11SNC-60x2500 Plate Bending Machine

- W11SNC-60x3000 Plate Bending Machine

- W11SNC-70x3000 Plate Bending Machine

- W11SNC-80x3000 Plate Bending Machine

- W11SNC-100x3000 Plate Bending Machine

- W11SNC-120x3000 Plate Bending Machine

- W11XNC series rolling machine

- Mechanical Plate Bending Machine

- W11-4x1500 Plate Bending Machine

- W11-4x2000 Plate Bending Machine

- W11-4x2500 Plate Bending Machine

- W11-6x2500 Plate Bending Machine

- W11-6x3000 Plate Bending Machine

- W11-8x2000 Plate Bending Machine

- W11-8x2500 Plate Bending Machine

- W11-10x3000 Plate Bending Machine

- W11-12x2000 Plate Bending Machine

- W11-12x2500 Plate Bending Machine

- W11-12x3000 Plate Bending Machine

- W11-16x2500 Plate Bending Machine

- W11-16x3000 Plate Bending Machine

- W11-20x2000 Plate Rolling Machine

- W11-20x2500 Plate Rolling Machine

- W11-20x3000 Plate Rolling Machine

- W11-25x2500 Plate Rolling Machine

- Asymmetric Plate Bending

- W11F-5x1500 Asymetry Plate Bending Machine

- W11F-6x1500 Asymetry Plate Bending Machine

- W11F-6x2000 Asymetry Plate Bending Machine

- W11F-6x2500 Asymetry Plate Bending Machine

- W11F-6x3000 Asymetry Plate Bending Machine

- W11F-8x2000 Asymetry Plate Bending Machine

- Production line

- Long Plate Bending Machine

- W11TNC-8x6000 Plate Bending Machine

- W11TNC-8x8000 Plate Bending Machine

- W11TNC-9x9000 Plate Bending Machine

- W11TNC-10x6000 Plate Bending Machine

- W11TNC-10x8000 Plate Bending Machine

- W11TNC-10x9500 Plate Bending Machine

- W11TNC-12x6000 Plate Bending Machine

- W11TNC-16x8000 Plate Bending Machine

- W11TNC-20x6000 Plate Bending Machine

- CNC Tube Bending Machine

- NC Tube Bending Machine

- DW38 NC Tube Bending Machine

- DW50 NC Tube Bending Machine

- DW63 NC Tube Bending Machine

- DW75 NC Tube Bending Machine

- DW89 NC Tube Bending Machine

- DW100 NC Tube Bending Machine

- DW110 NC Tube Bending Machine

- DW130NC NC Tube Bending Machine

- DW168 NC Tube Bending Machine

- Ironworker

- Q46Y Hole Punching Machine

- Q35Y-40 Ironworker

- Q35Y-30 Ironworker

- Q35Y-25 Ironworker

- Q35Y-20 Ironworker

- Q35Y-16 Ironworker

- Hydraulic Press

- YMG71 Series Composite Forming Press Machine

- YMG34 series H-frame hydraulic press

- YMG 27 series single action metal stamping press machine

- YMG28 series double actions metal drawing press machine

- YMG32 series four columns press machine

- YMG41 series C-frame press machine

- YMG89 series automobile girder forming press machine

- YMG46 series gantry type press machine

- Mechanical Press

- YC1 Series Single-crank Press Machine

- JB36 Series H-frame Double –Crank Press

- JH21 Series C-frame Fixed Table Press

- JL21 Series C-frame Fixed Press

- JY21 Series D-frame Fixed Table Press

- YS1 Series H-frame Single Crank Press

- YS2 Series H-frame Double- Crank Press

- Folding Machine

- W62Y-3x2500 folding machine

- W62Y-3x3200 Folding machine

- W62Y-4x2500 Folding Machine

- W62Y-4x3200 Folding machine

- Section Bending Machine

- W24S-45 Section Bending Machine

- W24S-75 Section Bending Machine

- W24S-100 Section Bending Machine

- W24S-140 Section Bending Machine

- W24S-180 Section Bending Machine

- W24S-260 Section Bending Machine

- Laser Cutting

- Parameters

- Pictures

- You May Like

- Inquiry Now

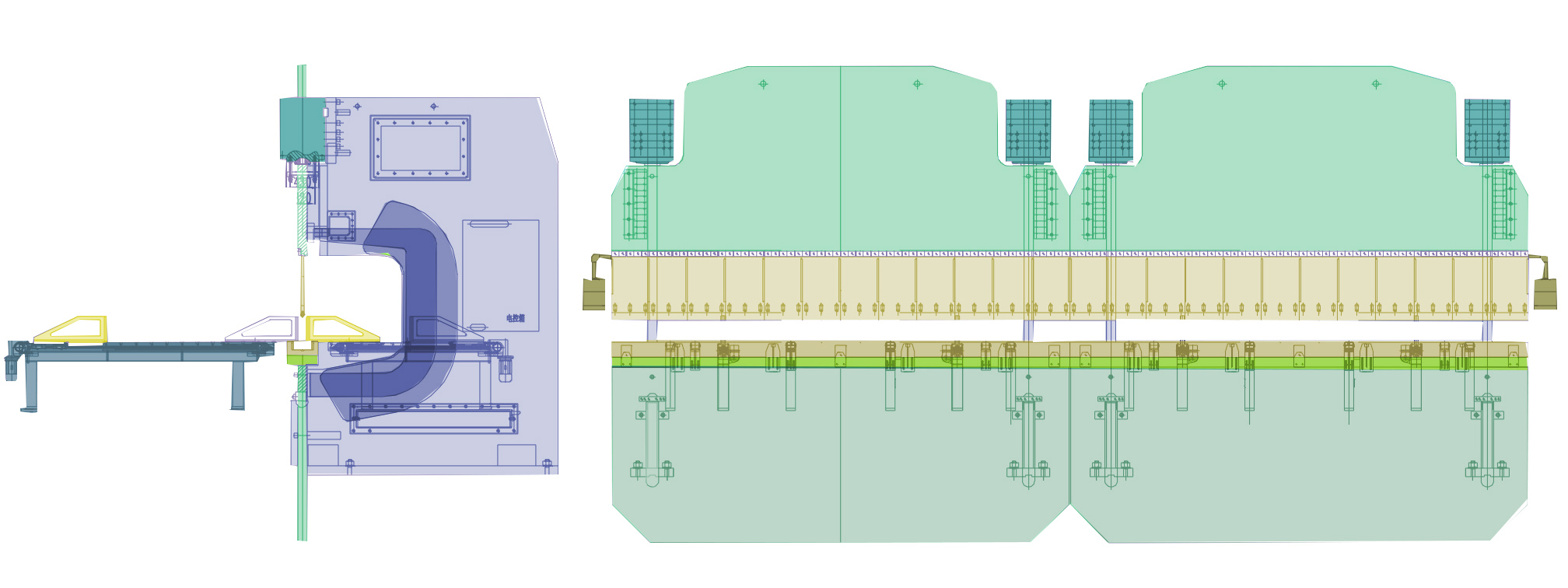

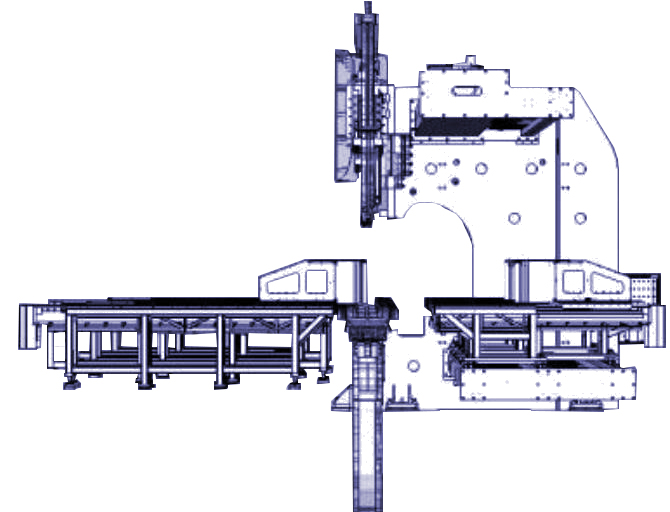

2xWE67K-1600/7000 CNC Press Brake in Tandem

CNC Press Brake in Tandem adopts two or three Electric-hydraulic synchronous press brakes to work together. CNC press brakes in tandem has all of the advantages of the WE67K CNC electric-hydraulic synchronous press brake, which are designed to bend the super length work piece, such as the conical lighting pole, pyramid lighting pole, auto beam, big length constructive parts, etc

Parameters:

|

Nominal force |

KN |

2x16000 |

|

|

Length of working table |

mm |

2x7000 |

|

|

Distance between uprights |

mm |

5600 |

|

|

Throat depth |

mm |

1300 |

|

|

Max. daylight |

mm |

1300 |

|

|

Main motor power |

KW |

2x2x55 |

Optional |

|

Main oil pump |

L/min |

2x2x100 |

Optional |

|

Approaching speed |

mm/s |

70 |

|

|

Bending speed |

mm/s |

7 |

|

|

Returning speed: |

mm/s |

70 |

|

|

Length |

mm |

2x6300 |

Without the side unloading system |

|

Width |

mm |

4500 |

Without the front feeding system |

|

Height(over land) |

mm |

5900 |

|

Accuracy:

Y1.Y2.Y3.Y4 axis re-position: ≤+0.05mm

Y1.Y2.Y3.Y4axis position: ≤+0.03mm

X axis re-position: ≤+0.02mm

X axis position: ≤+ 0.05mm

Test bending angle: + 1°/3000 mm

Test straightness: ±0.75/1000 mm

Features

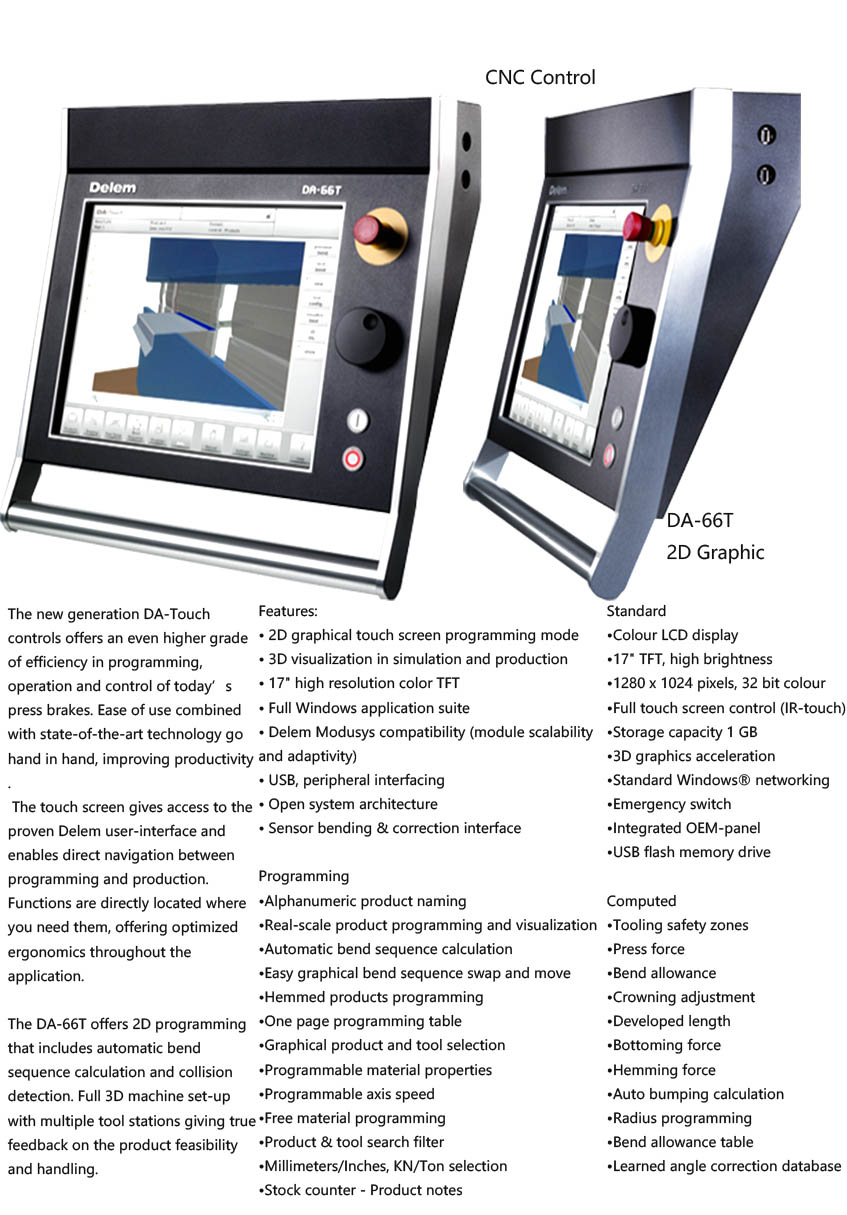

--World class dedicated controller from Delem

--Two press brake CNC controlled to work synchronous

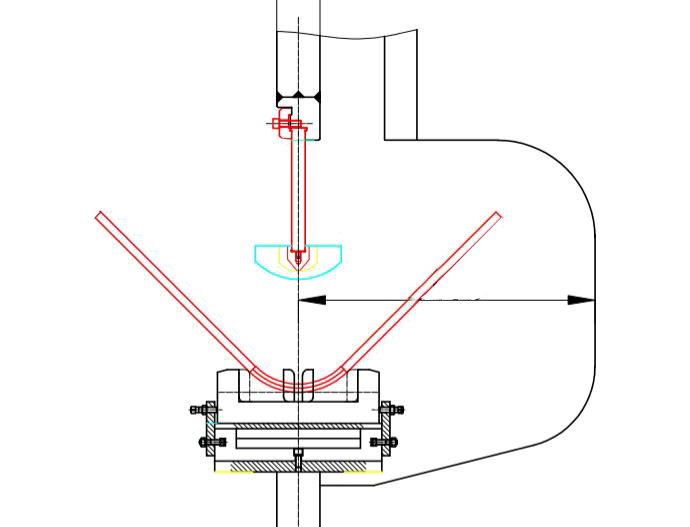

--Y1-Y2-Y3-Y4 axis CNC control

--Close loop proportional hydraulics for beam synchronization.

-- Opening width adjustable lower die,

--Fixed punching handle + variable punching head

--Highly Precise proportional valve to control accurate beam movement.

--The power pack is supplied by Bosch –Germany.

--Back gauge consist of hardened & ground ball screw,

--liner motion bearings and AC servo drive for accurate position up to 0.05 mm

--DA-66T 2D Touch Screen CNC controller

--Cylinder

--Throat depth

--Feeding table & back pushed

Components

|

1 |

Main electric components |

SIEMENS & Schneider or OMRON |

|

2 |

Main motor |

SIEMENS BEIDE |

|

3 |

Oil pump |

SUNNY(under license of SUNNY Hydraulic .INC (U.S.A) |

|

4 |

Valve |

BOSCH-REXROTh |

|

5 |

Seal |

NOK |

|

6 |

CNC controller |

DELEM |

|

7 |

Touch screen |

DELEM |

|

8 |

Synchronous control |

DELEM |

|

9 |

Light encoder |

FAGOR |

|

10 |

Linder guider |

ABBA |

|

11 |

Ball screw |

ABBA |

|

12 |

Servo driver |

ESTUN |

Optional choose:

--Motorized front sheet supporter + front feeder

--Side material unloading system

--Side material pusher

--Front crane to lift the material

--Different kind of mould

--Pipe strengthening machine

--Pipe welding machine

.JPG)

.JPG)

.JPG)

CNC press brake in tandem, tandem press brake, hydraulic press brake, plate bending machine, press brake for light pole, press brake in tandem, press brake

--Application

.JPG)

.JPG)