- How to set the knife clearance?

- Shearing angle and plate thickness

- QC11Y shearing and QC12Y shearing

- How to choose the capacity of a press brake?

- The spring-back of the material

- How the CNC press brake work?

- How to choose the V-die for a press brake ?

- How to solve barrel defect during roll bending

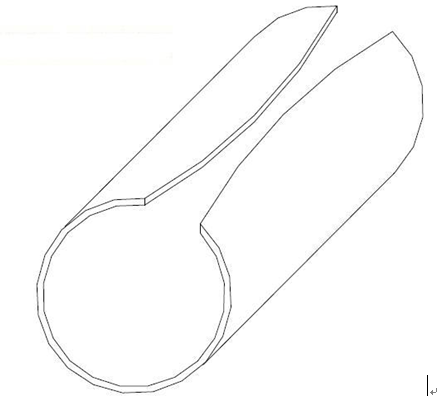

- How to solve reel defect during roll bending

- New foundation for 2019

You have reel defect when the tube is closed in the middle but open at its end. This defect can be caused by the roll bi-conicity.

CAUSE 1: The plate you are using is too thin in relation to the machine performance

SOLUTION 1: There is no other solution than bending the material with a lower Capacity machine

CAUSE 2: The plate pinching pressure is to weak

SALUTION 2: Slightly lift the bottom roller to increase the pinch force.