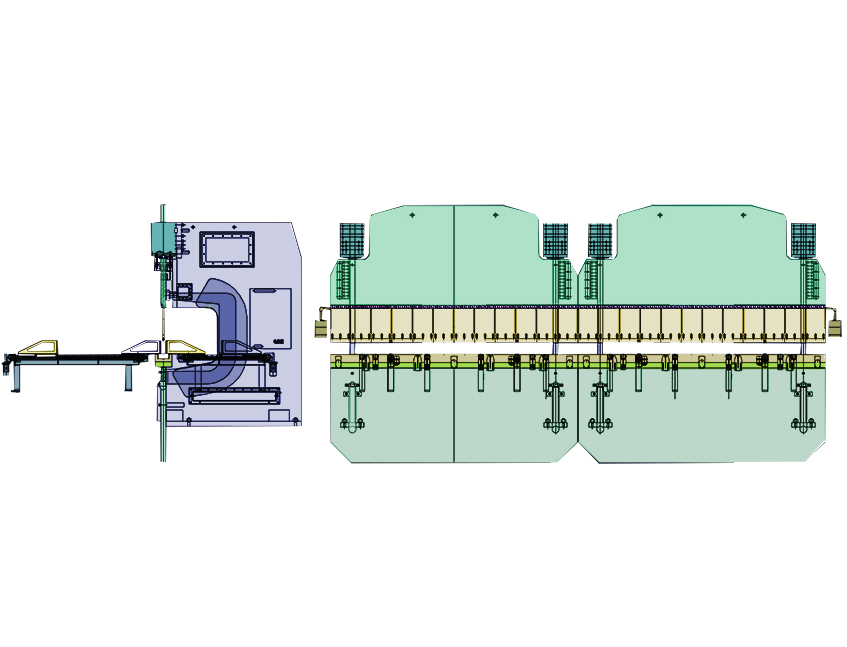

2xWE67K-400T4000 CNC Press Brake in Tandem

CNC Press Brake in Tandem adopts two or three Electric-hydraulic synchronous press brakes to work together. CNC press brakes in tandem has all of the advantages of the WE67K CNC electric-hydraulic synchronous press brake, which are designed to bend the super length work piece, such as the conical lighting pole, pyramid lighting pole, auto beam, big length constructive parts, etc

Parameters

|

Nominal force |

KN |

2x4000 |

|

|

Length of working table |

mm |

2x4000 |

|

|

Distance between uprights |

mm |

3100 |

|

|

Throat depth |

mm |

400 |

optional |

|

Max. daylight |

mm |

520 |

optional |

|

Main motor power |

KW |

2x30 |

|

|

Main oil pump |

L/min |

2x50 |

|

|

Approaching speed |

mm/s |

70 |

|

|

Bending speed |

mm/s |

7 |

|

|

Returning speed: |

mm/s |

70 |

|

|

Length |

mm |

2x4200 |

Without the side unloading system |

|

Width |

mm |

2000 |

Without the front feeding system |

|

Height(over land) |

mm |

3430 |

|

Features:

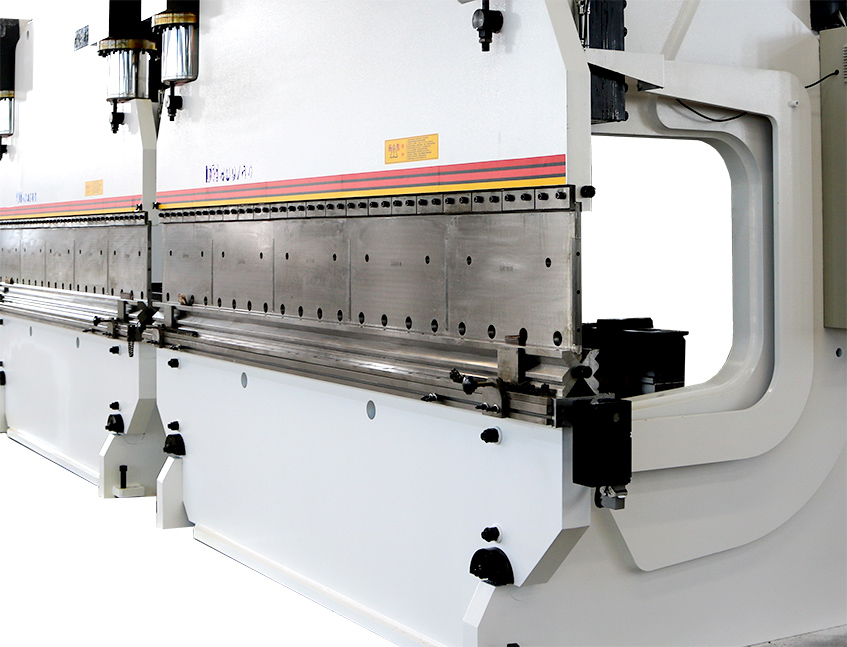

-- two CNC press brakes in tandem

-- suite bend long size plate till 8meters

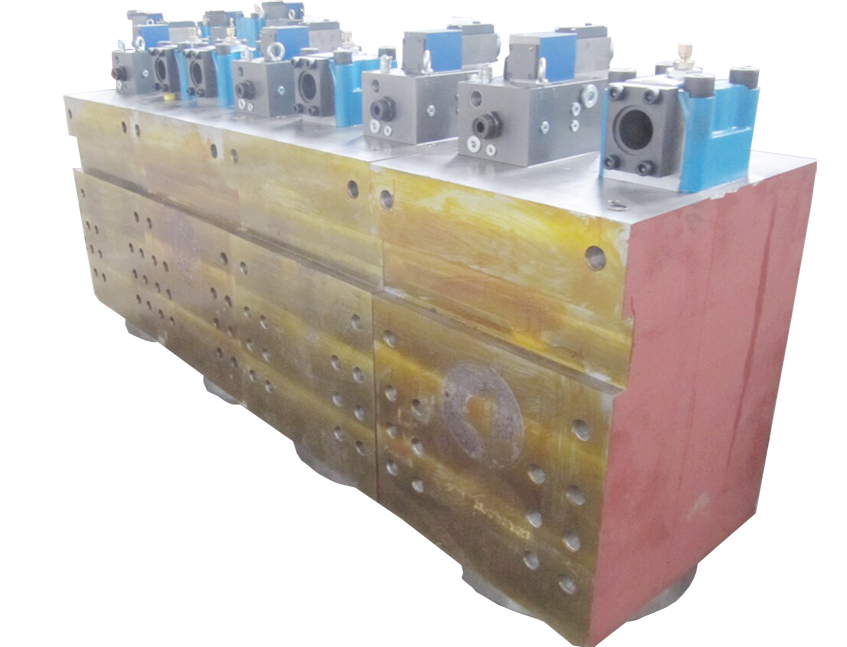

--REXROTH highly precise proportional valve to control accurate beam movement

-- accurate & fine beam position control by micro limit switch

--hydraulic cylinder with twin type sealing low & high pressure and hard chrome

--CNC controlled mechanical pulling-rod anti-crowing device(V)

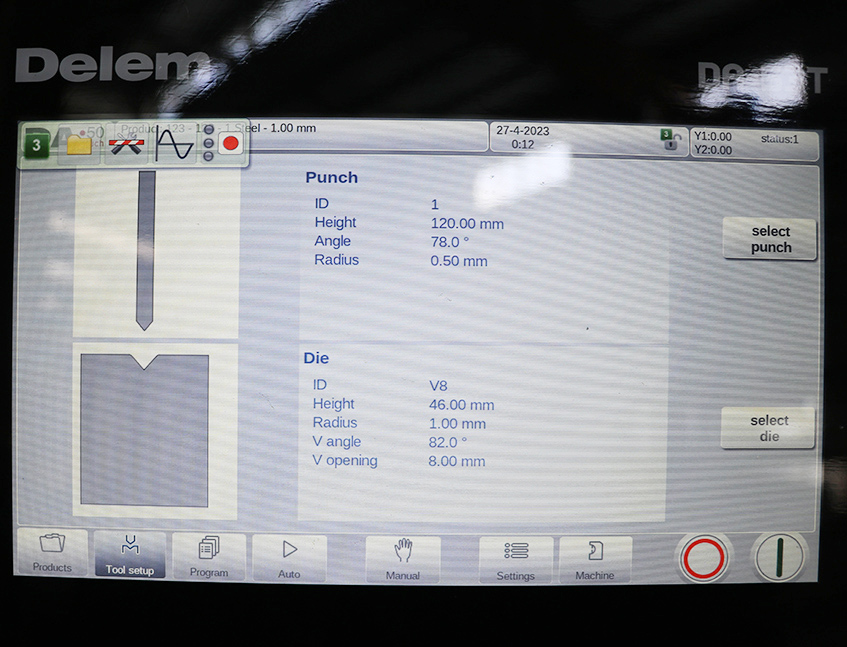

-- Variable-V die

--Fixed adapter + variable punching tool

--Highly Precise proportional valve to control accurate beam movement

--Back gauge consist of hardened & ground ball screw

--DA-53T CNC controller

--REXROTH valve hydraulic system

--Motorized back gauge

--Crowning device

--Punch & multi-V die

--GIVI lineal scale

-

-

Name:*

-

Email:*

-

Phone:*

-

Company Name:

-

Comments:*Note:HTML is not translated!