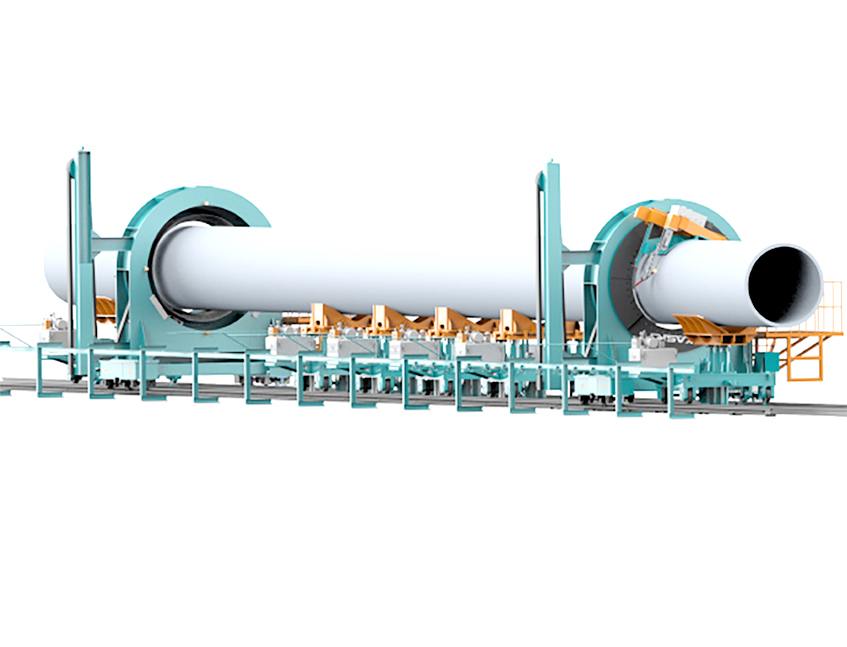

Offshore Double-end Cutting Machine

Max. cutting diameter:2800mm,Suitable for large, long and thick(100mm) pipes

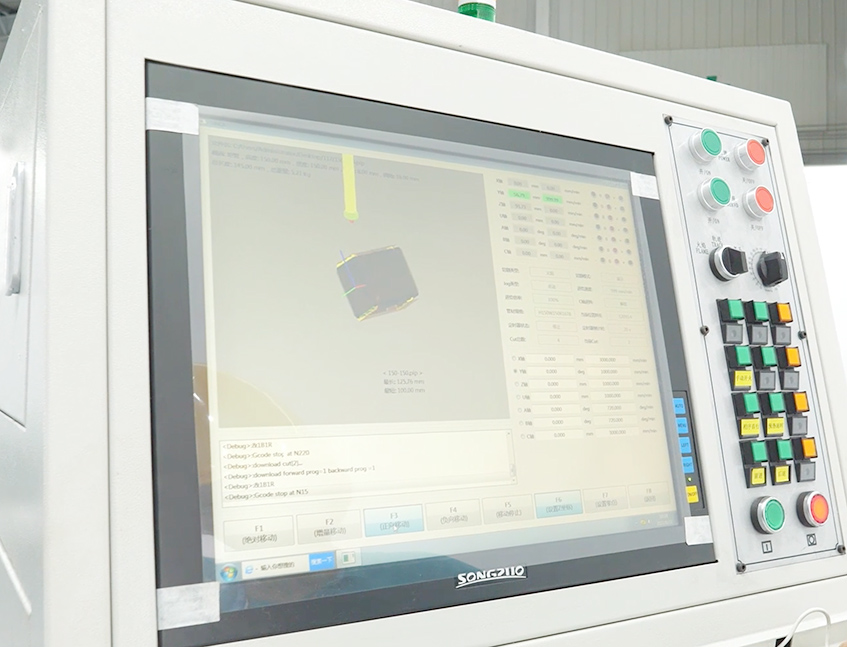

High automation and cutting quality, featuring optimized nesting and multiple programming methods

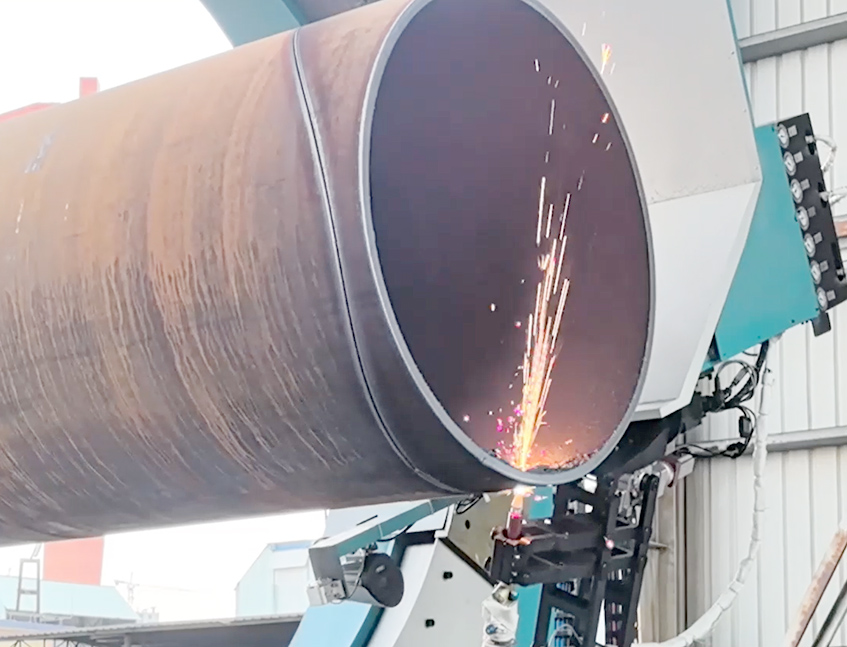

Processing types include end processing and intersection cutting.

Precision Double-end Cutting:

The double-end cutting system enables communication between two control units, automatically acquiring origin positions to ensure synchronized cutting accuracy, which significantly improves processing efficiency and quality. The software connects with Tekla 3D models, supporting the cutting of components with varying diameters to expand processing capabilities

Intelligent Cutting Compensation:

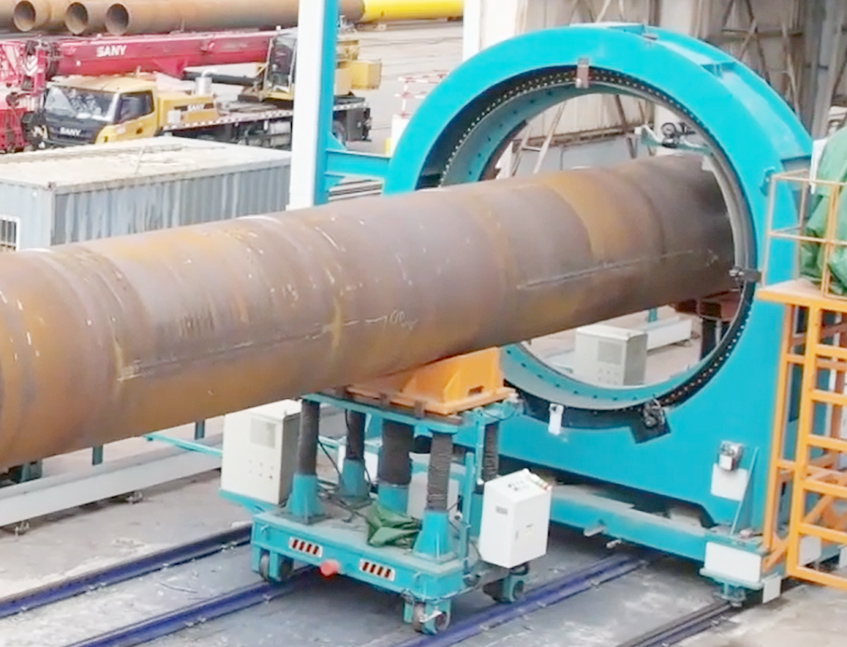

The primary and secondary cutting stations utilize laser scanning to collect and analyze pipe ovality data, implementing real time cutting compensation to effectively solve material shape deviations to ensure cutting precision.

Accurate Pipe Centering:

Four quadrant-mounted lasers on both primary and secondary units capture alignment data, feeding real time position feed back to the main console. independent touchscreens allow micro-adjustments in four directions, ensuring pipe centering.

Parameter

|

|

HG2800 |

|

Diameter of pipe (mm) |

2800 |

|

Wall thickness (mm) |

6-80 |

|

Cutting length (m) |

9-40 (customed) |

|

Cutting method |

Flame |

|

Driving system |

Servo motor |

|

Cutting speed |

10-700mm/min |

|

Moving speed |

10-6000mm/min |

|

Accuracy of cutting length |

±5mm (40m) |

|

Bevel cutting |

≤ ±55º |

Sample

-

-

Name:*

-

Email:*

-

Phone:*

-

Company Name:

-

Comments:*Note:HTML is not translated!