- JCO Pipe Forming Press

- Press Brake

- CNC Press Brake

- Heavy Duty Press Brake

- NC Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- CNC Servo Press Brake

- Corrugation Press Brake

- Pipe Cutting Machine

- Plate Bending Machine

- 4-rollers Plate Bending Machine

- 3-rollers Hydraulic Plate Bending Machine

- 3-rollers Mechanical Plate Bending Machine

- 3-rollers Long Plate Bending Machine

- 3-rollers Asymmetric Plate Bending Machine

- 3-rollers Variable Geometry Plate Bending Machine

- Shearing Machine

- Guillotine Shearing Machine

- Swing Beam Shearing Machine

- CNC Shearing Machine

- Heavy Duty Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Cutting & Welding Line

- Offshore Double-End Cutting Machine

- Tube Cutting Machine

- Large Pipe Cutting Machine

- Pipe Cutting Machine

- H-beam Processing line

- H-beam Assembling-Welding-Straightening Machine

- H-beam Horizontal-type Flange Plate Straightening Machine

- H-beam Gantry-type Welding Machine

- U-Rib Assembling Machine

- H-beam Flange Plate Straightening Machine

- U-Rib External Welding Machine

- H-beam Horizontal-type Assembling Machine

- T-beam Assembling & Welding Line

- Box-beam Assembling Machine

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Parameters

- Pictures

- You May Like

- Inquiry Now

WH67K-160/6300 Torsion CNC Press Brkae

WH67K series CNC Torsion Press Brake is a torsion synchronous press brake which equipped with the YL60H CNC controlled system, which the Y axis( beam) and X axis (back gauge) is CNC controlled.

Parameters

|

1 |

Nominal pressure |

1600 |

KN |

|

|

2 |

Bending width |

6300 |

mm |

|

|

3 |

Distance between uprights |

4800 |

mm |

|

|

4 |

Stroke |

200 |

mm |

|

|

5 |

Max. opening height |

400 |

mm |

|

|

6 |

Throat depth |

320 |

mm |

|

|

7 |

Working table length |

6000 |

mm |

|

|

8 |

Approaching speed |

80 |

mm/s |

|

|

9 |

Bending speed |

8 |

mm/s |

|

|

10 |

Returning speed |

80 |

mm/s |

|

|

11 |

Main motor power |

11 |

KW |

|

|

12 |

Oil pump |

25 |

mr/r |

|

|

13 |

Machine length |

6400 |

mm |

|

|

14 |

Machine width |

1550 |

mm |

|

|

15 |

Machine height |

2850 |

mm |

Overland |

Features

▲ YL60H (E300) CNC controller

▲ Torsion bar synchronous system

▲ Automatic angle bending

▲ Beam position is automatically calculated

▲ SIEMENS BEIDE motor

▲ SUNNY quiet pump

▲ Three operation model( Jog,Single,Continuous)

▲ Y-X axes CNC controlled, servo drive

▲ International quality hydraulics system

▲ Accurate & fine beam position control by micro limit switch.

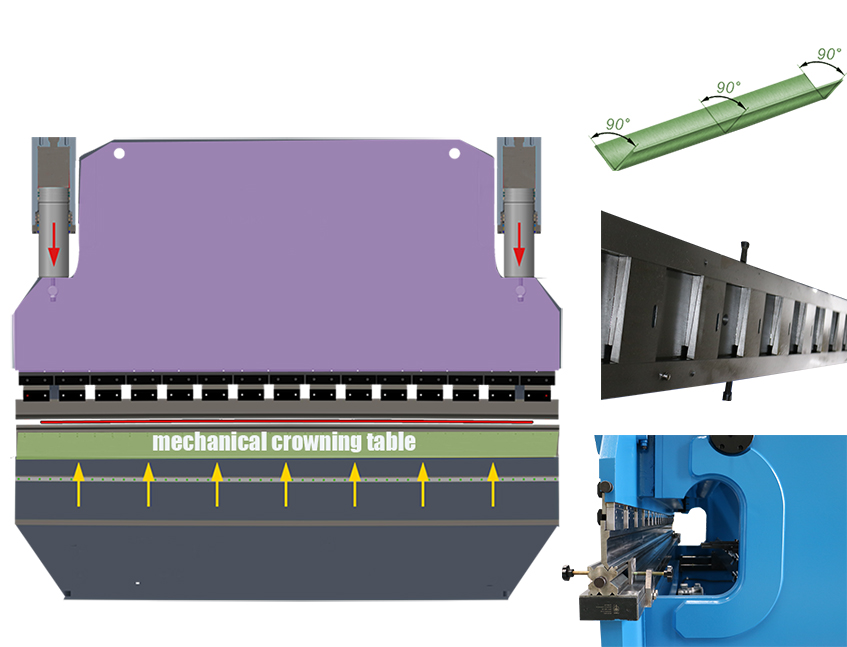

▲ Mechanical crowing table

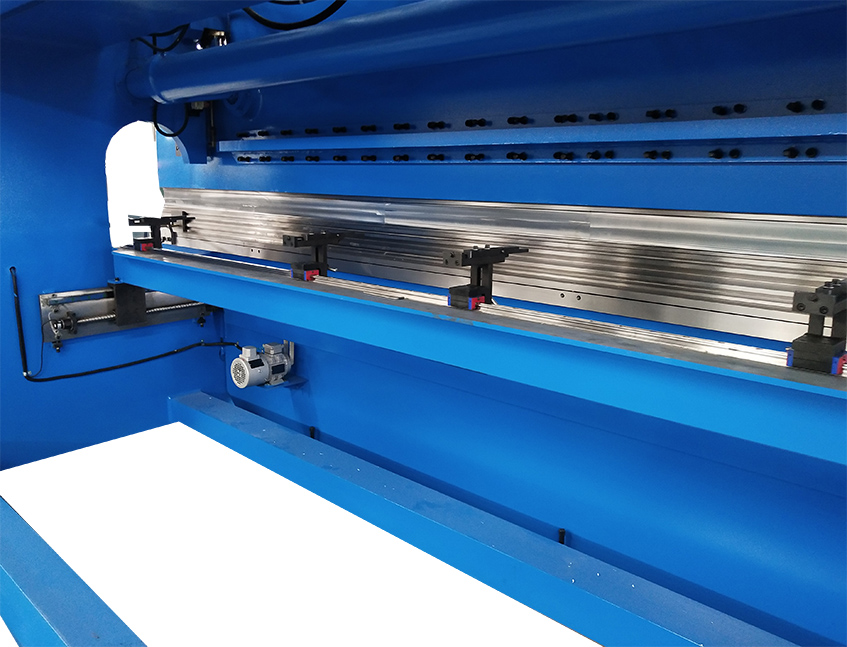

▲ Ball screw & linear rail back gauge

▲ Manual operated R axis

▲ Front sheet support

▲ Punch quick clamping system

▲ 4-face multi-V die

▲ mm/inch

▲ English language

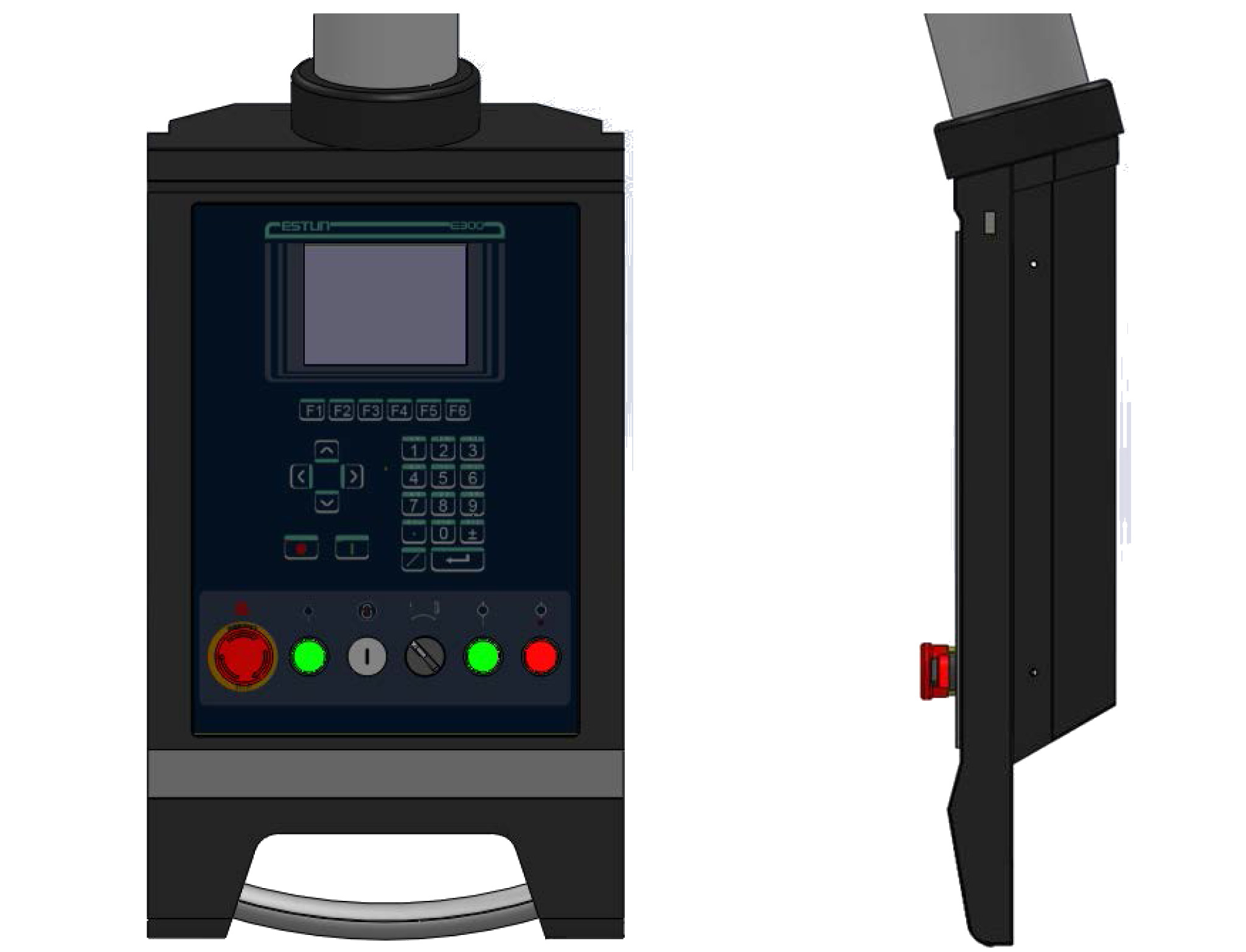

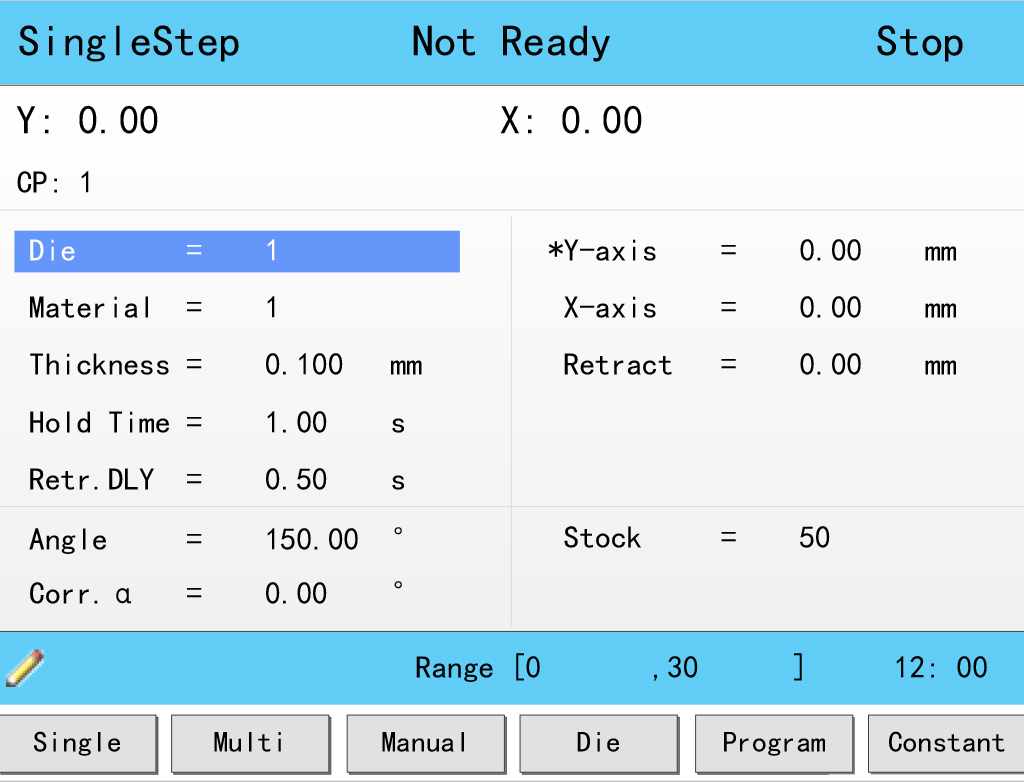

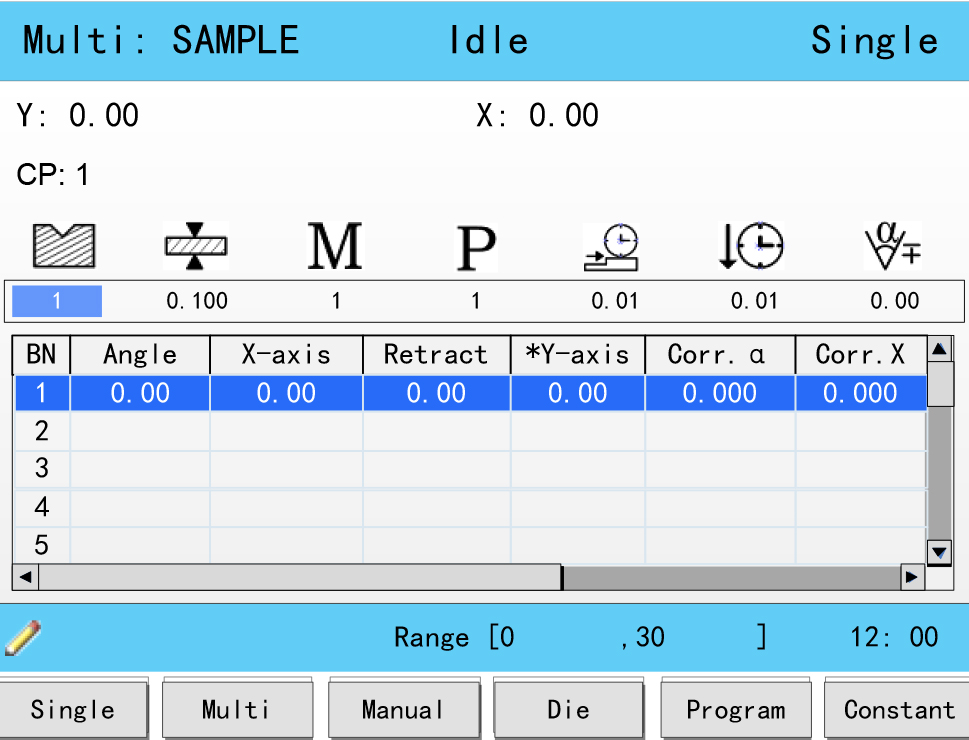

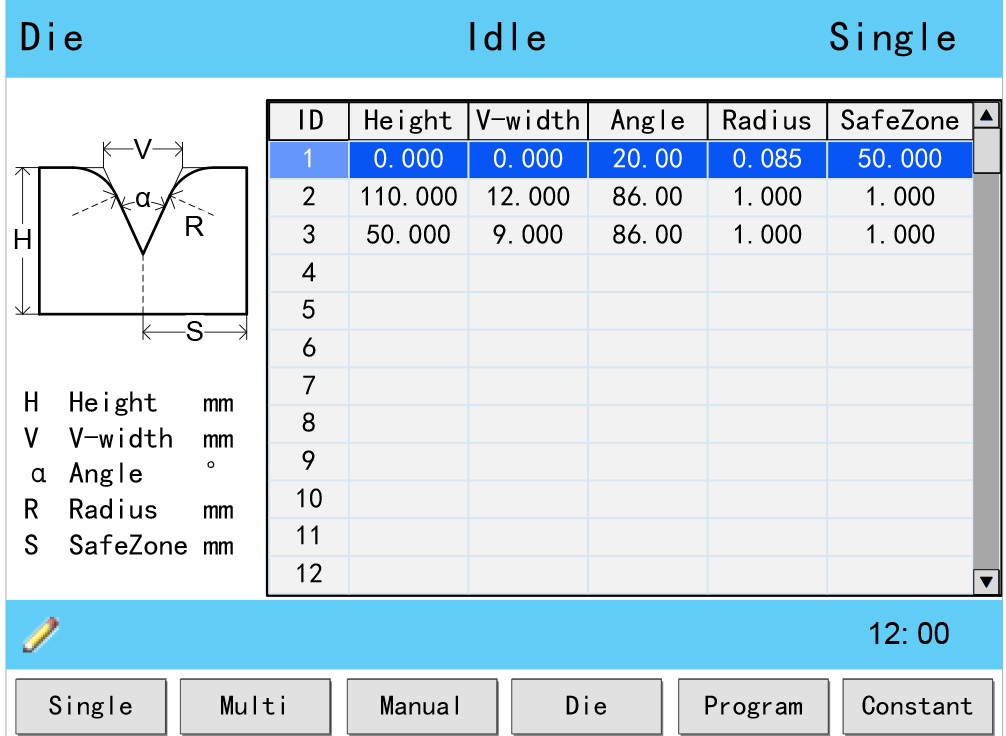

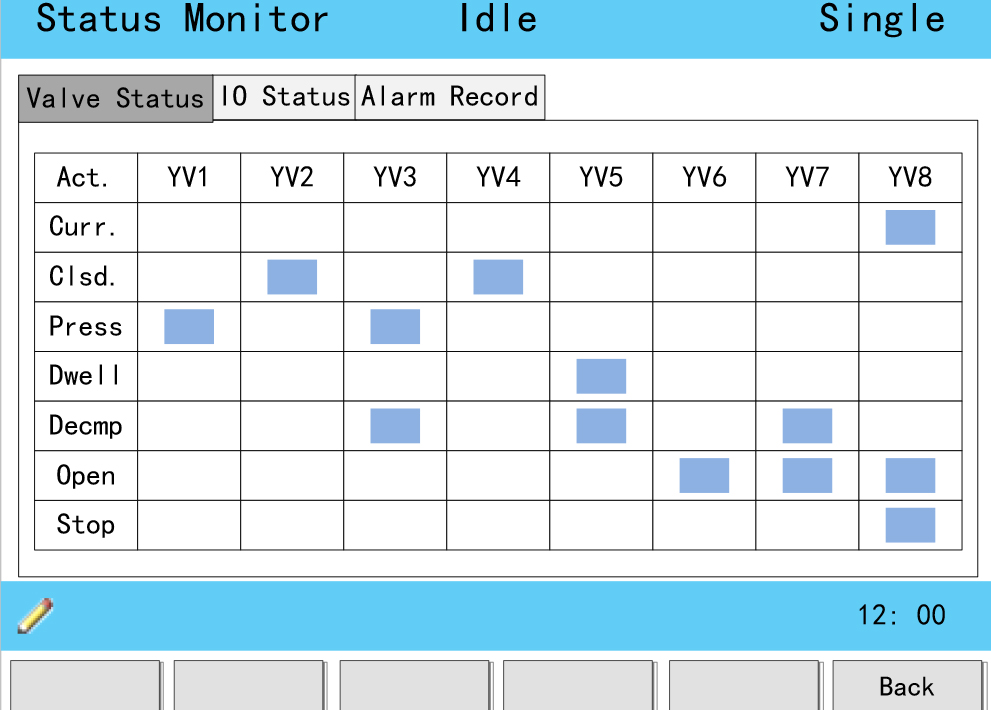

--YL60 CNC controller

The YL60H is a dedicated CNC (numerical control) device for the Torsion Press Brake, which combines the expertise of many years and provides a complete economic solution for the Torsion Bending Machine with the support of unique drive control technology.

The YL60H device adopts the integral product structure, built-in high-performance A8 processor, and configures 5.6 inch, 640 × 480 dot matrix, 18 full color display screen, and integrated IO ports, serial ports and USB port.

The YL60H device is designed to be operated via the buttons on the front panel. At the same time, the pump switch and the emergency stop button are installed in the customized suspension cabinet to meet the user's requirements. Its friendly interface, easy to use, practical function.

--Mechanical crowing table

--Punch & die

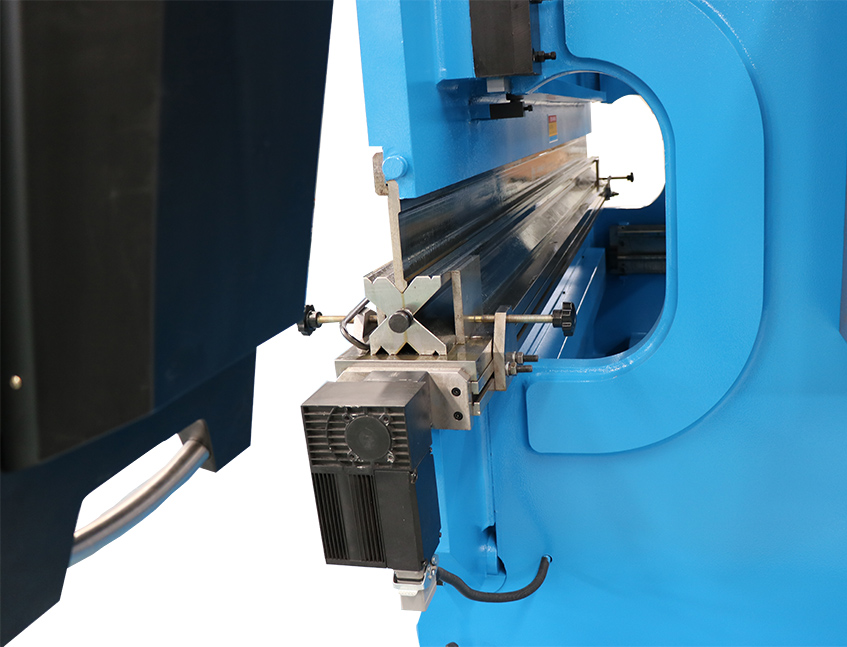

--Back gauge

--Pipe Connection

--Automatic Crowing Table as Optioanl Choose

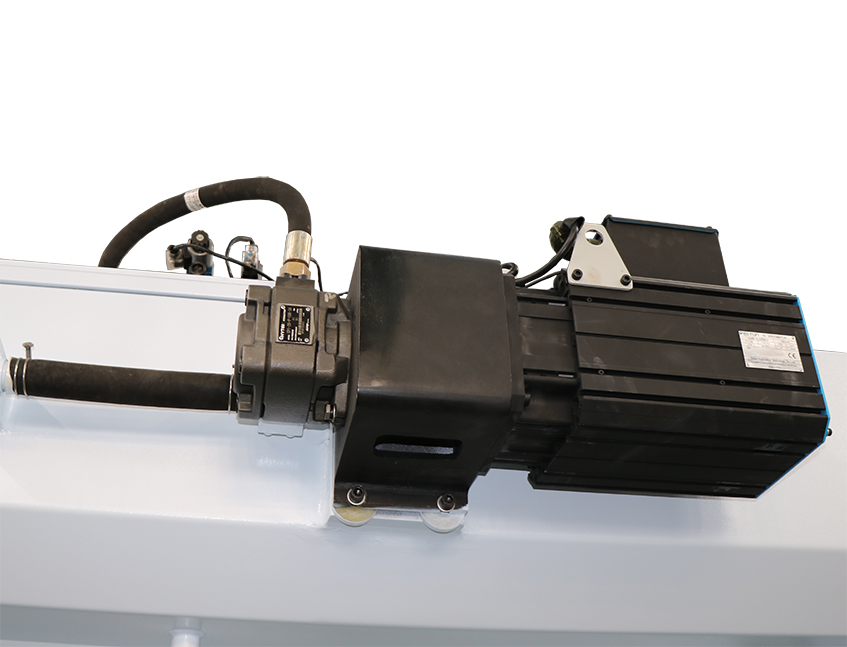

--Servo motor as Optional Choose

--Motorized R axis as Optional Choose

press brake, hydraulic press brake, plate bending machine, hydraulic bender, bending machine,