- JCO Pipe Forming Press

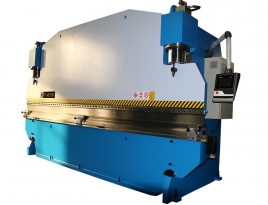

- Press Brake

- CNC Press Brake

- Heavy Duty Press Brake

- NC Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- CNC Servo Press Brake

- Corrugation Press Brake

- Pipe Cutting Machine

- Plate Bending Machine

- 4-rollers Plate Bending Machine

- 3-rollers Hydraulic Plate Bending Machine

- 3-rollers Mechanical Plate Bending Machine

- 3-rollers Long Plate Bending Machine

- 3-rollers Asymmetric Plate Bending Machine

- 3-rollers Variable Geometry Plate Bending Machine

- Shearing Machine

- Guillotine Shearing Machine

- Swing Beam Shearing Machine

- CNC Shearing Machine

- Heavy Duty Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Cutting & Welding Line

- Offshore Double-End Cutting Machine

- Tube Cutting Machine

- Large Pipe Cutting Machine

- Pipe Cutting Machine

- H-beam Processing line

- H-beam Assembling-Welding-Straightening Machine

- H-beam Horizontal-type Flange Plate Straightening Machine

- H-beam Gantry-type Welding Machine

- U-Rib Assembling Machine

- H-beam Flange Plate Straightening Machine

- U-Rib External Welding Machine

- H-beam Horizontal-type Assembling Machine

- T-beam Assembling & Welding Line

- Box-beam Assembling Machine

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Parameters

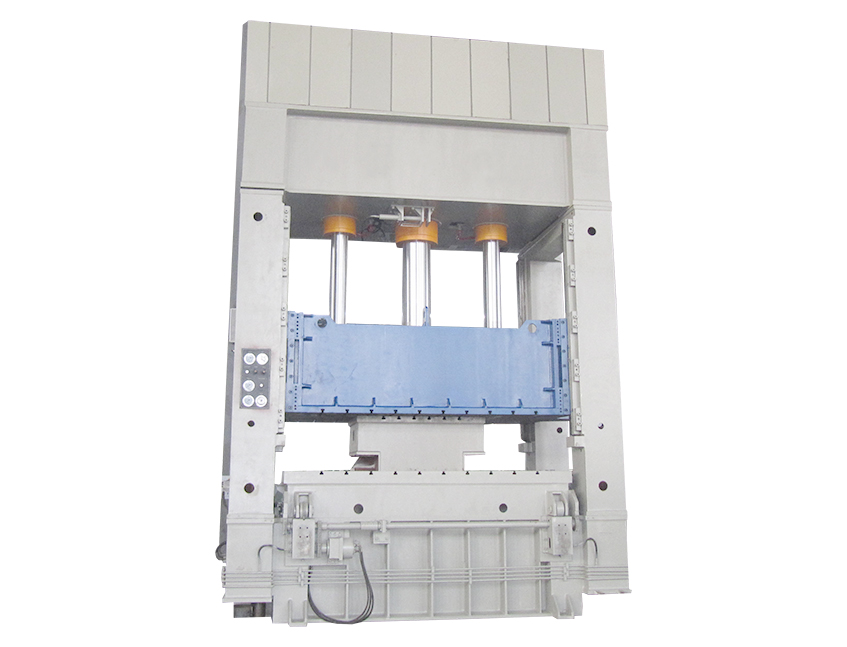

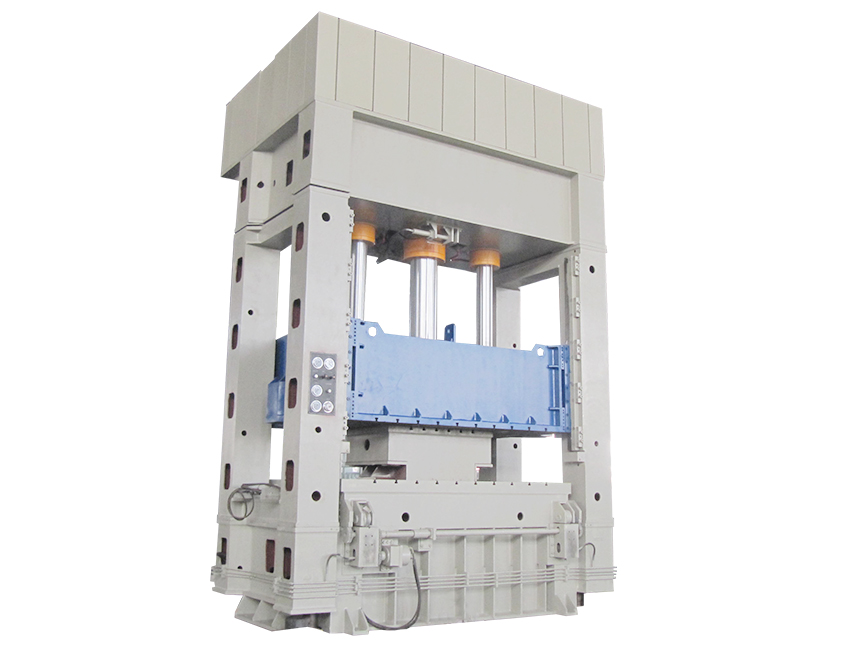

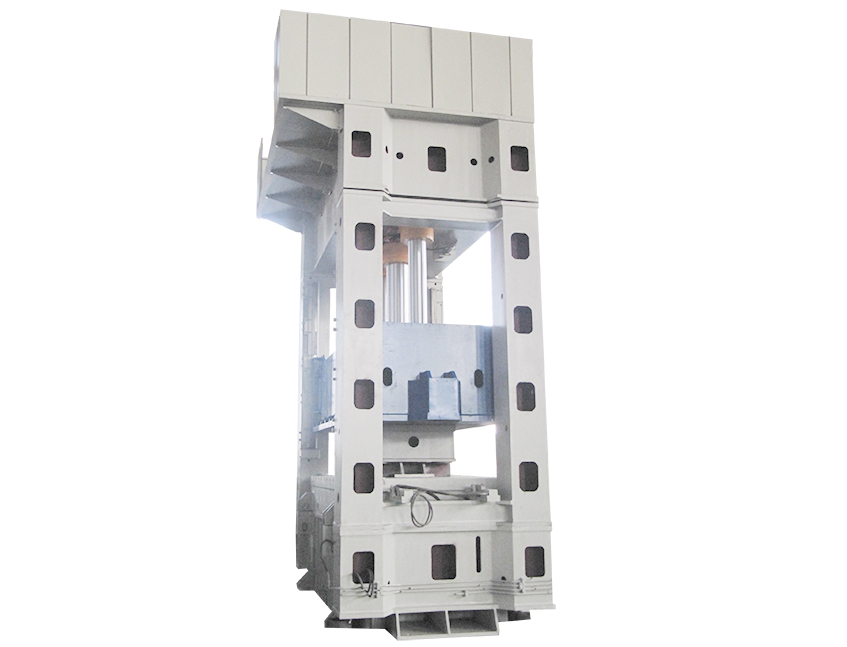

- Pictures

- You May Like

- Inquiry Now

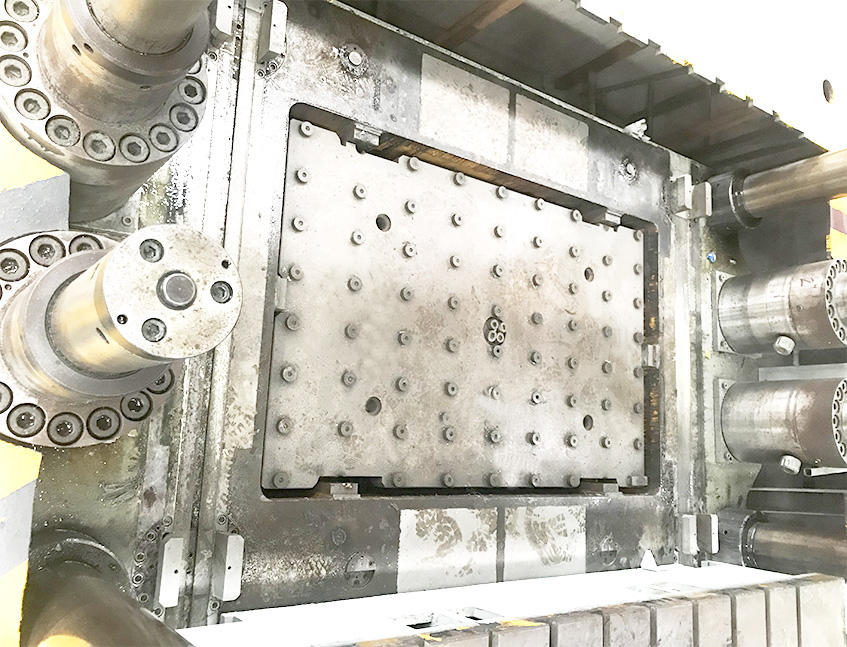

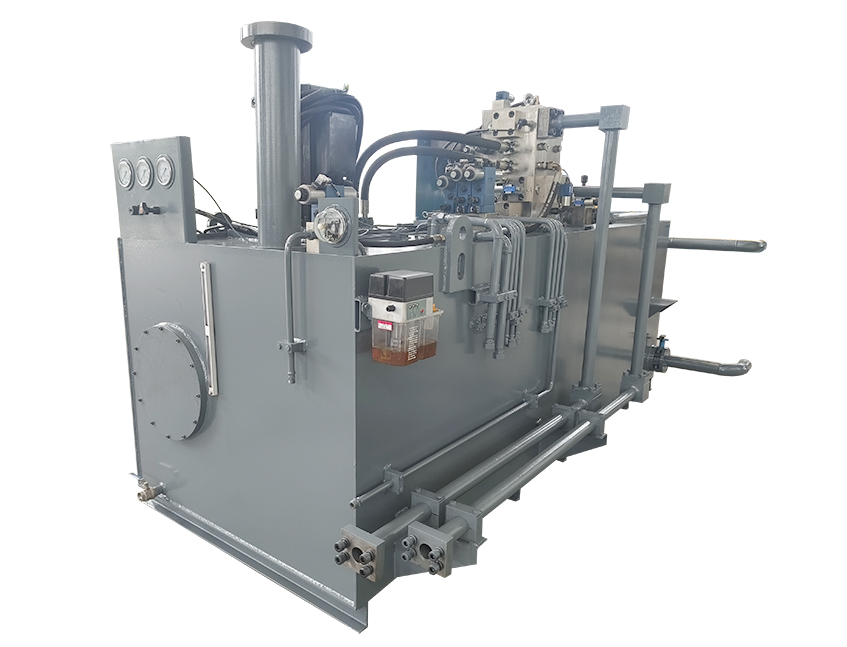

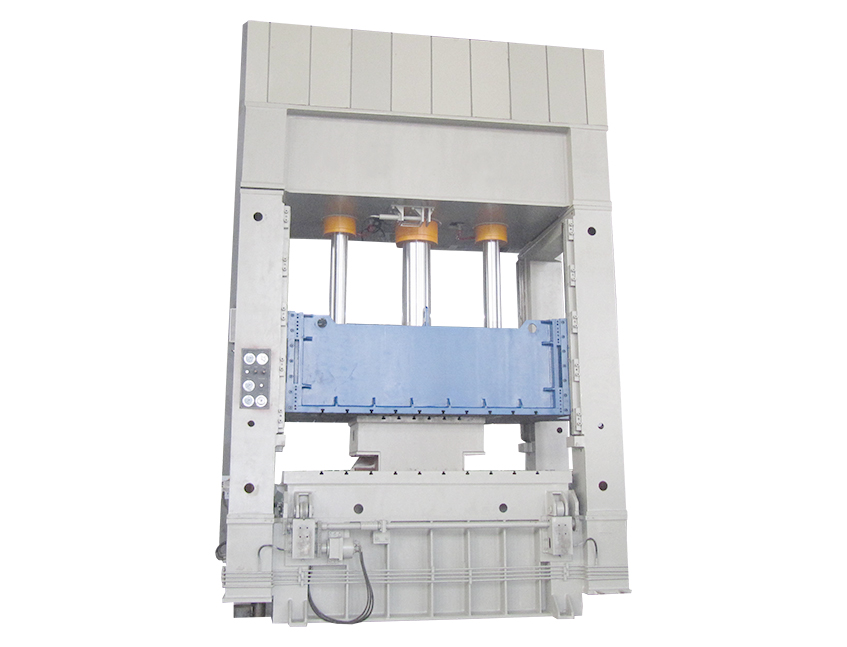

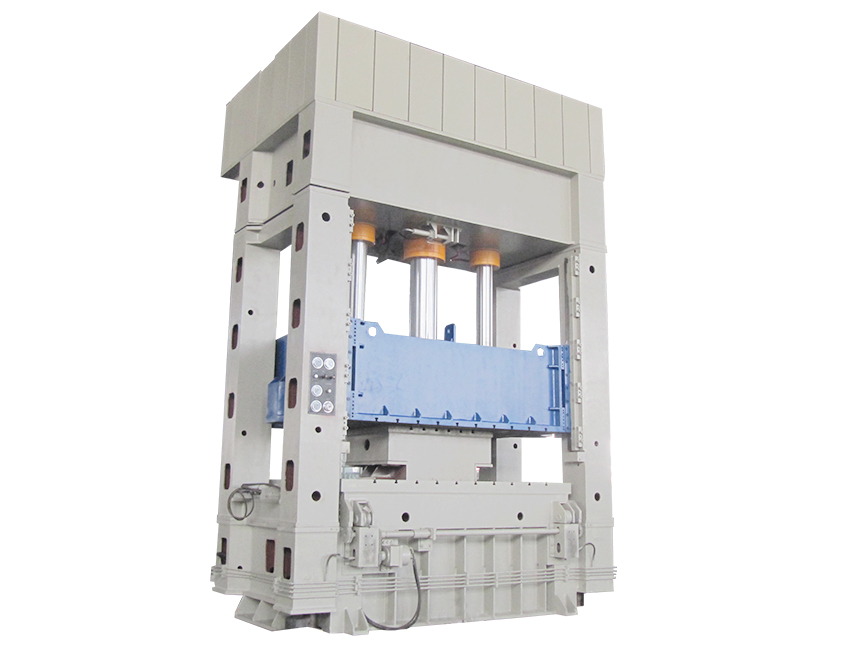

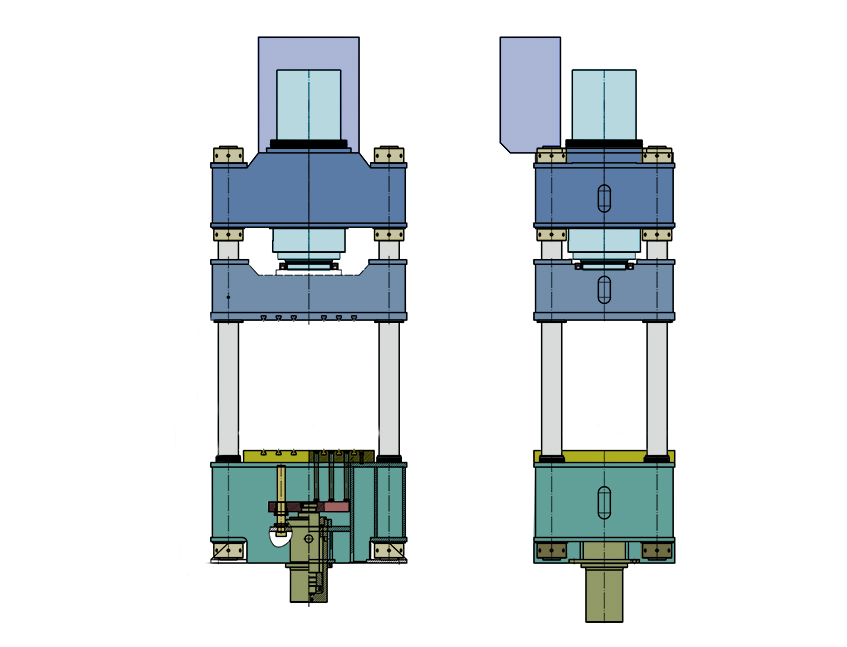

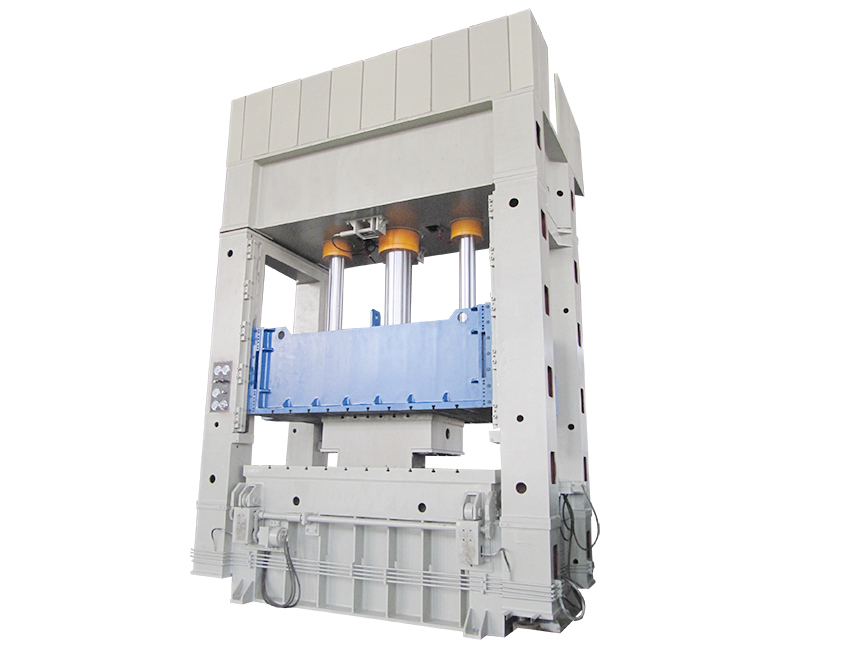

YMG27-series Single Action Press

The YMG27 series hydraulic press machines are widely used for metal drawing use.

It’s most suitable to use for the following field:

Household electronics: cooker, parts of refrigerator, etc

Automobile parts: bodywork, oil tanker, brake disc, chassis, bumper, etc

Kitchen utensils: sink, pot,

Main features:

--Widely used for sheet metal drawing, bending, flanging, stamping, forming, etc.

--Main structure is steel welded, heat treatment to remove the inner stress, with high rigidity and stability

--Cartridge valves widely used for hydraulic system, reliable, durable and less hydraulic impact.

--Independent electrical control system, reliable, audio-visual and very convenient for maintenance, main electric components are SIEMENS.

--Centralized button control station.

--Operation choice inch-action and single action.

--slider stroke range, pressure and press speed can be set according practical use.

--With pressure keep and time delay functions.

--Hydraulic cushion is equipped beneath the work table, adequate knock out holes are prepared at the hydraulic cushion.

--Bi-manual buttons operating system to improve the safety.

--Light curtain to be equipped to help to improve the safety during the pressing period.

Parameter

| NO | Unit | YMG27-100 | YMG27-200 | YMG27-315 | YMG27-400 | YMG27-500 | YMG27-630 | YMG27-800 | YMG27-1000 | YMG27-1250 | YMG27-1500 | YMG27-2000 | ||

| 1 | Rated force | KN | 1000 | 2000 | 3150 | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 15000 | 20000 | |

| 2 | Returning force | KN | 100 | 450 | 600 | 650 | 900 | 1200 | 1200 | 1800 | 2500 | 3200 | 4000 | |

| 3 | Max. daylight | mm | 1000 | 1100 | 1250 | 1350 | 1500 | 1500 | 1500 | 1500 | 1800 | 1800 | 1800 | |

| 4 | Max. pressure | KN | 200 | 630 | 1000 | 1000 | 1600 | 2000 | 3000 | 3000 | 3500 | 4000 | 5000 | |

| 5 | Cushion stroke | mm | 200 | 250 | 350 | 350 | 350 | 350 | 350 | 350 | 400 | 400 | 400 | |

| 6 | slider stroke | mm | 600 | 700 | 800 | 800 | 900 | 900 | 900×550 | 1000 | 1000 | 1200 | 1200 | |

| 7 | slider speed | Approaching | mm/s | 120 | 100 | 100 | 100 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Pressing | mm/s | 10-14 | 10-15 | 8-10 | 6-10 | 10-14 | 8-12 | 10-15 | 8-15 | 6-18 | 10-14 | 10-15 | ||

| Returning | mm/s | 120 | 70 | 60 | 55 | 70 | 55 | 90 | 70 | 70 | 90 | 120 | ||

| 8 | Cushion speed | Knocking out | mm/s | 50 | 40 | 20 | 15 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Returning | mm/s | 100 | 80 | 40 | 30 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | ||

| 9 | Table size | L-R | mm | 720 | 1000 | 1200 | 1200 | 1400 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| F-B | mm | 580 | 900 | 1200 | 1200 | 1400 | 1600 | 1800 | 2000 | 2000 | 2000 | 2000 | ||

| 10 | Cushion table size | L-R | mm | 450 | 600 | 800 | 800 | 900 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 |

| F-B | mm | 450 | 500 | 800 | 800 | 900 | 1000 | 1250 | 1500 | 1500 | 1500 | 1500 | ||

| 11 | Loading weight of moving table | T | / | / | / | / | 15 | 15 | 15 | 15 | 30 | & | ||

Applications

-- Suitable for drawing, bending, forming, stamping and flanging processes, especially for the following fields

--Automobile parts production such as vehicle bodywork, brake disc, oil tank, chassis, rear axle and bumper,etc.

--Household electronics: washing machine parts, electric cooker, TV set parts, refrigerator parts

--Kitchen utensils: kitchen sinks, pots, stainless steel articles and other containers

--Others: tractor, motorcycle, aircraft and aerospace industry

.jpg)

.jpg)