- JCO Pipe Forming Press

- Press Brake

- CNC Press Brake

- Heavy Duty Press Brake

- NC Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- CNC Servo Press Brake

- Corrugation Plate Bending Line

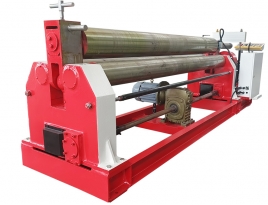

- Plate Bending Machine

- 4 Rollers Plate Bending

- Universal Plate Bending Machine

- Mechanical Plate Bending Machine

- Long Plate Bending Machine

- Asymmetric Plate Bending

- Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Laser Cutting

- Parameters

- Pictures

- You May Like

- Inquiry Now

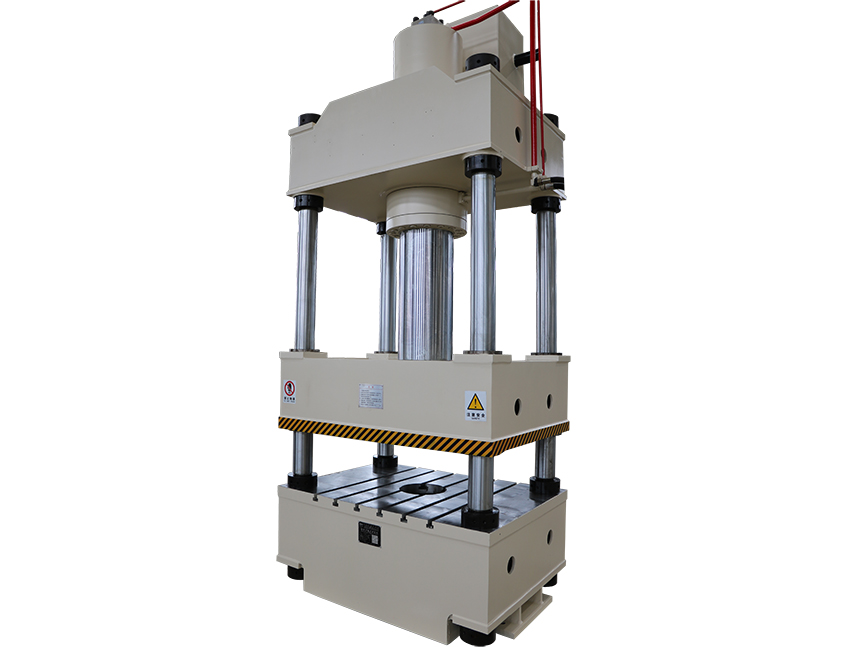

YMG32-series hydraulic press machine

The YMG32 series hydraulic press machines are widely used for drawing, bending, flanging, cold extruding, blanking processes, strengthening, powder forming, abrasive products forming, plastic forming, insulation material forming, etc

Main features:

--Main structure is steel welded, heat treatment to remove the inner stress, with high rigidity and stability.

--Three-slider + four-column structure, computer optimized design, simple structure but with high performance.

--Cartridge valves widely used for hydraulic system, reliable, durable and less hydraulic impact.

--Independent electrical control system, reliable, audio-visual and very convenient for maintenance, main electric components are SIEMENS.

--Centralized button control station.

--Operation choice inch-action and single action.

--slider stroke range, pressure and press speed can be set according practical use.

--With pressure keep and time delay functions.

--Knock out cylinder at the center of the work table to help to remove the lower mould or work piece.

--Bi-manual buttons operating system to improve the safety.

--Light curtain to be equipped to help to improve the safety during the pressing period.

BASIC STRUCTURE

The main structure of the press consists of three horizontal steel structures and four columns, with high rigidity. The four columns connect two stationary plates (the crown and the work table). There is a (up/down) sliding plate (beam) between the stationary plates. The hydraulic cylinder mounted between the crown and the beam are driving the beam and delivering the rated pressing force

The hydraulic unit

The hydraulic unit is placed on the side of the press and connected to it by flexible high pressure hoses and a multi-signal electrical connection. The unit consists of one main pump for pressing action, combined with an oil tank and filter unit.

Optional choice:

--Moving table

--Oil heating system

--Oil cooling system

--beam locking system

--beam-support-rod

--mould protection system

--oil tanker placed on crown

--H-frame structure

| NO | Specification | Unit | YHD32-40 | YHD32-63 | YHD32-100 | YHD32-100A | YHD32-160 | YHD32-160B | YHD32-200 | YHD32-315 | YHD32-400 | YHD32-500 | YHD32-500C | YHD32-630 | YHD32-800 | YHD32-1000 | YHD32-1250 | YHD32-1600 | YHD32-2000 | |

| 1 | Rated force | KN | 400 | 630 | 1000 | 1000 | 1600 | 1600 | 2000 | 3150 | 4000 | 5000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 | 20000 | |

| 2 | Knock-out force | KN | 120 | 190 | 190 | 190 | 400 | 400 | 400 | 630 | 630 | 1000 | 1000 | 1000 | 1600 | 2000 | 2000 | 2000 | 3200 | |

| 3 | Max. pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| 4 | slider stroke | mm | 350 | 450 | 600 | 600 | 700 | 700 | 700 | 800 | 800 | 900 | 900 | 900 | 1000 | 1000 | 1000 | 1000 | 1300 | |

| 5 | Knock-out stroke | mm | 150 | 200 | 200 | 200 | 200 | 200 | 250 | 300 | 300 | 350 | 350 | 350 | 400 | 400 | 400 | 400 | 500 | |

| 6 | Max. daylight | mm | 700 | 750 | 880 | 880 | 900 | 1000 | 1100 | 1250 | 1250 | 1500 | 1500 | 1600 | 1600 | 1600 | 1600 | 1600 | 1800 | |

| 7 | slider speed | Approaching | mm/s | 20 | 20 | 22 | 120 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 150 | 150 | 200 |

| Pressing | mm/s | 14 | 14 | 14 | 14 | 12 | 12 | 8 | 6-8 | 5-7 | 5 | 6 | 10 | 8 | 10 | 6-10 | 6-10 | 4-9 | ||

| Returning | mm/s | 45 | 120 | 47 | 120 | 70 | 70 | 52 | 60 | 45 | 70 | 70 | 60 | 70 | 60 | 50 | 40 | 70 | ||

| 8 | Table size | L-R | mm | 500 | 560 | 720 | 720 | 780 | 1000 | 1000 | 1260 | 1240 | 1400 | 2400</span& | ||||||

Applications

Drawing ,bending ,flanging, cold extruding, blanking processes for metal materials; straightening, press-in and forming processes for powder and abrasive products, plastic and insulation materials.