- JCO Pipe Forming Press

- Press Brake

- CNC Servo Press Brake

- CNC Press Brake

- Heavy Duty Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- Corrugation Plate Bending Line

- NC Press Brake

- Plate Bending Machine

- 4 Rollers Plate Bending

- Universal Plate Bending Machine

- Mechanical Plate Bending Machine

- Long Plate Bending Machine

- Asymmetric Plate Bending

- Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Laser Cutting

- Parameters

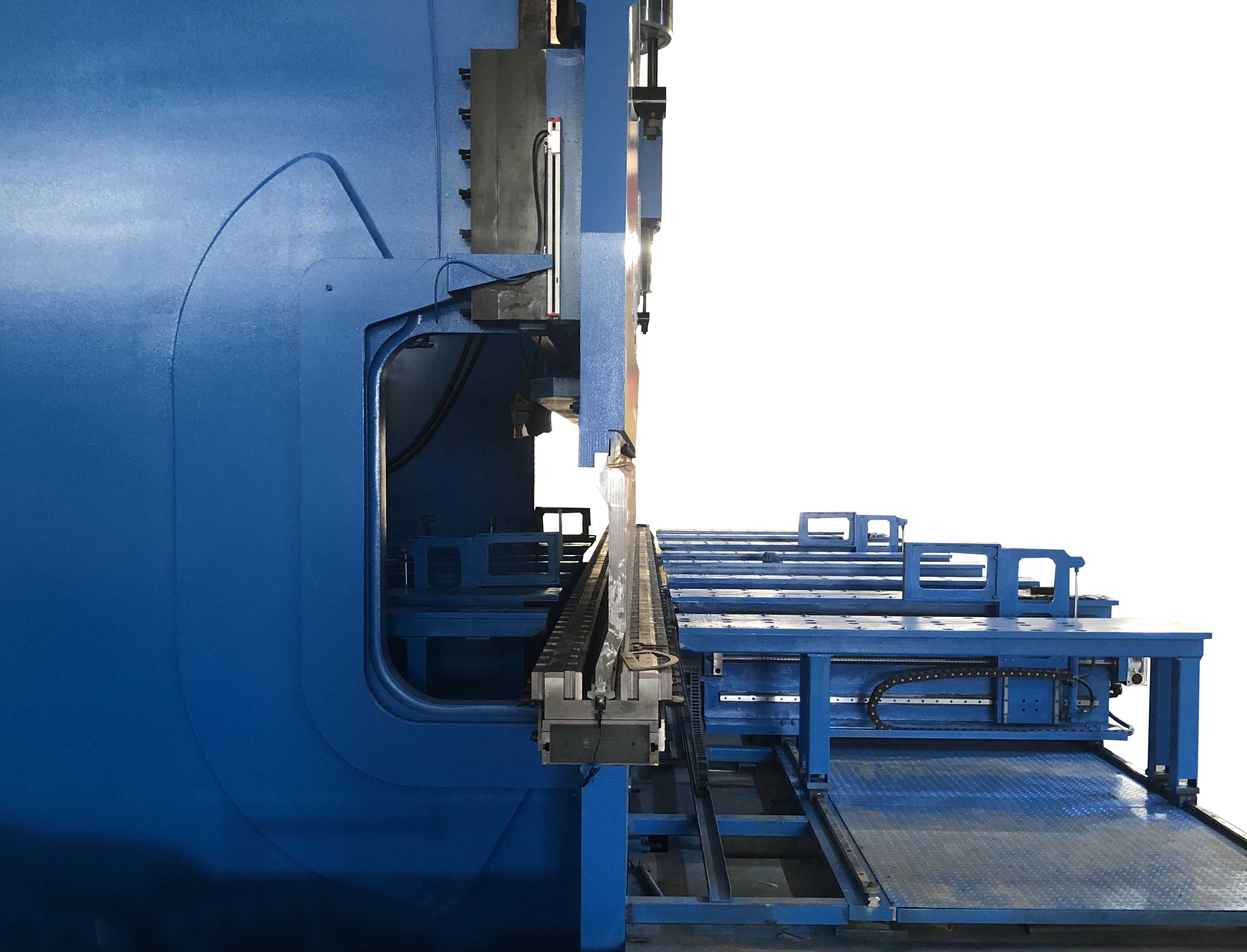

- Pictures

- You May Like

- Inquiry Now

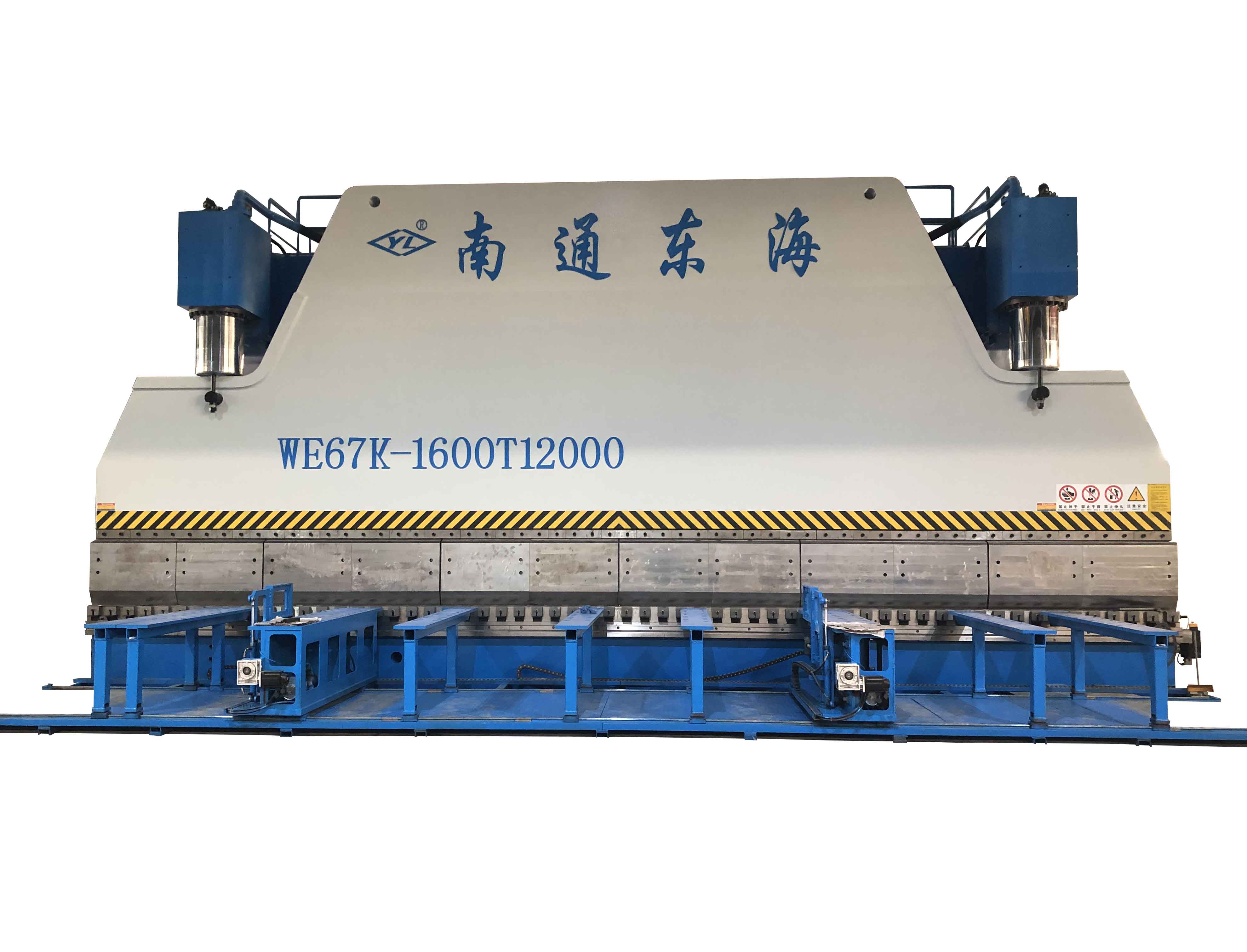

WE67K-1600/12000 CNC electric-hydraulic synchronous Press Brake Machine

Parameters:

| MODEL | BENDING FORCE | BENDING LENGTH | UPRIGHT DISTANCE | OPEN HEIGHT | THROAT DEPTH | BEAM STROEK | MOTOR POWER |

| WE67K-1600T/12000 | 16000 | 20000 | 9050 | 10000 | 1200 | 400 | 2×55 |

CNC controlled axis

The CNC Control is used for 3+1 Axis Control or more.

Synchronized beam axes Y1 & Y2

Back Gauge axis X

Automatic anti-deflection axis V

With modern CNC control, more axis can be CNC controlled, such as X1,X2, R, Z

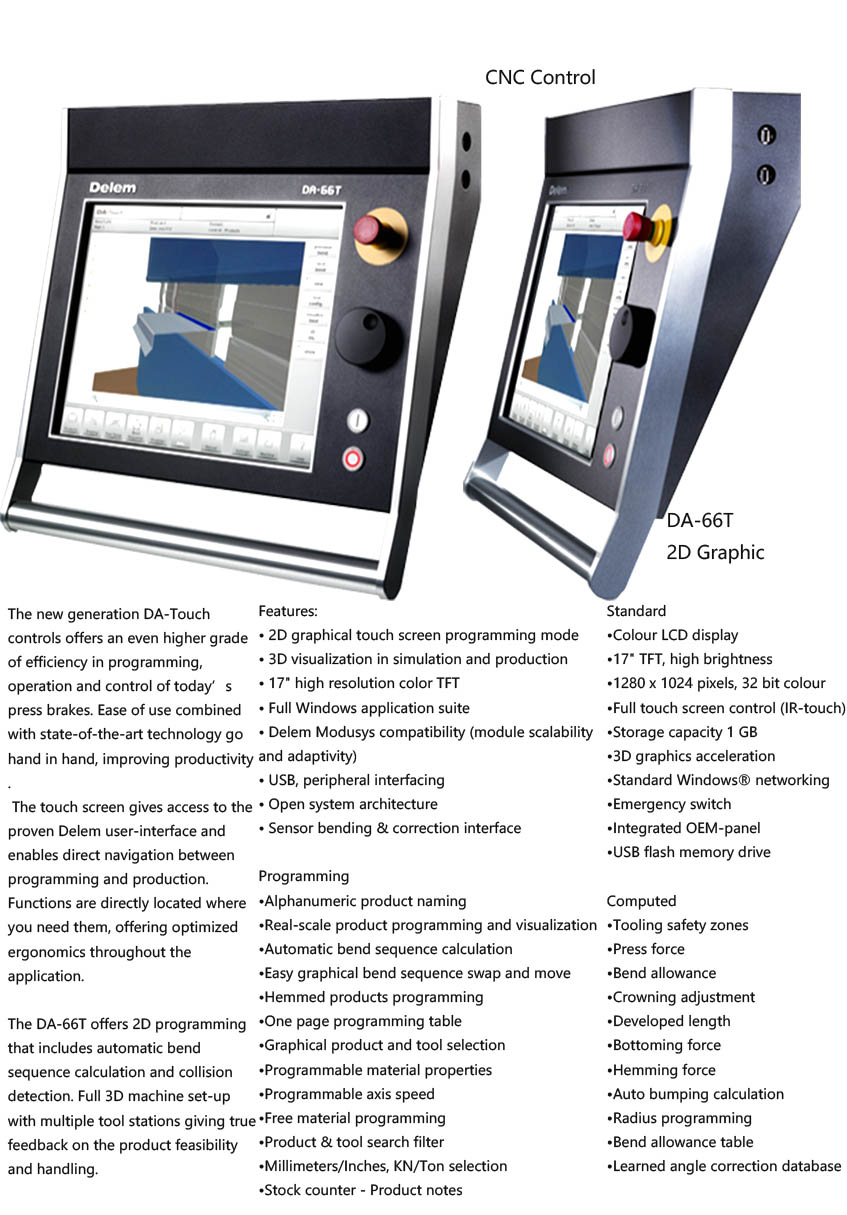

CNC controller

The program gives facility to bend different bending degrees; different back gauge positions & different open positions. It has a facility to save different programs and it can be reloaded as & when required.

The machine can be equipped with some high finishing optional choice, like back gauge X1, X2,R & Z axis

Anti-deflection equipment

WE67K CNC control press brakes are supplied with the automatic anti-deflection system, by mechanical or hydraulic.

Features

--World class dedicated controller from Delem

--Y1-Y2-X +V 3+1 or more axis control

--Bend angle & Depth Mode program.

--Highly Precise press brake scale for Y1, Y2 axis.

--Close loop proportional hydraulics for beam synchronization.

--Zero leak sealing of hydraulic cylinders.

--Hardened & ground Multi “V” Die & Punch.

--Quick release die clamps.

--Highly Precise proportional valve to control accurate beam movement.

--The power pack is supplied by Bosch –Germany.

--Back gauge consist of hardened & ground ball screw,

--liner motion bearings and AC servo drive for accurate position up to 0.05 mm.

--Back gauge

--Feeding table