- JCO Pipe Forming Press

- Press Brake

- CNC Press Brake

- Heavy Duty Press Brake

- NC Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- CNC Servo Press Brake

- Corrugation Plate Bending Line

- Plate Bending Machine

- 4 Rollers Plate Bending

- Universal Plate Bending Machine

- Mechanical Plate Bending Machine

- Long Plate Bending Machine

- Asymmetric Plate Bending

- Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Laser Cutting

- Parameters

- Pictures

- You May Like

- Inquiry Now

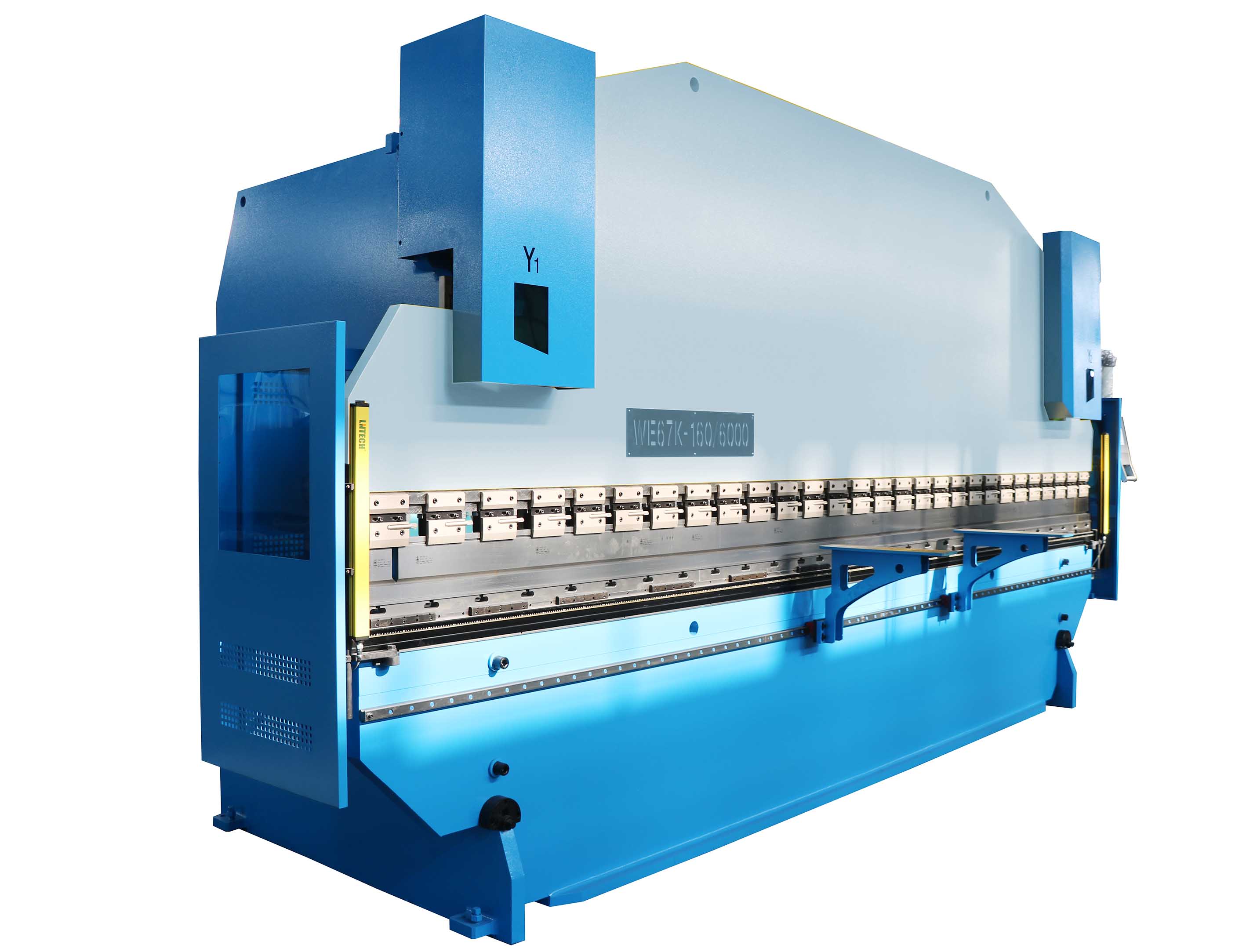

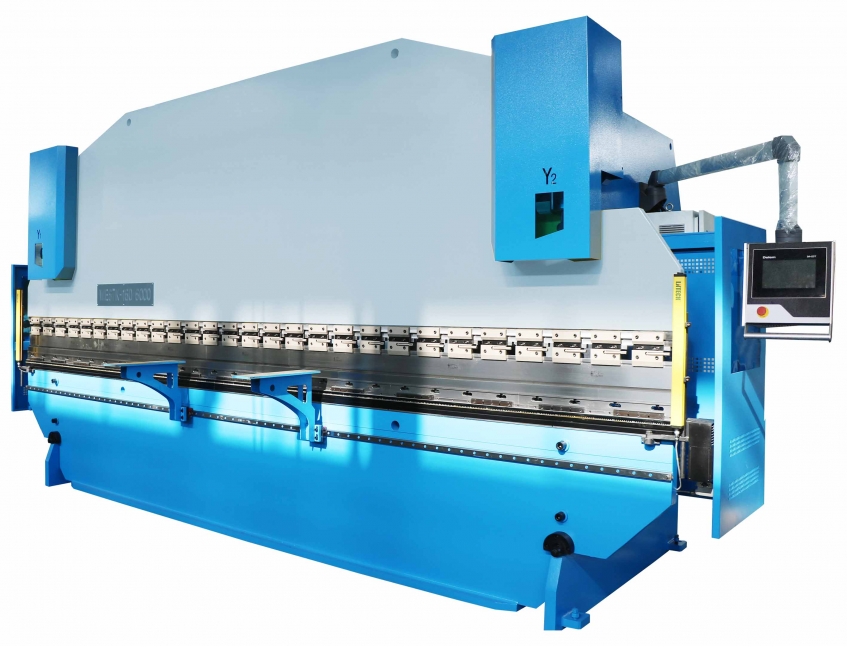

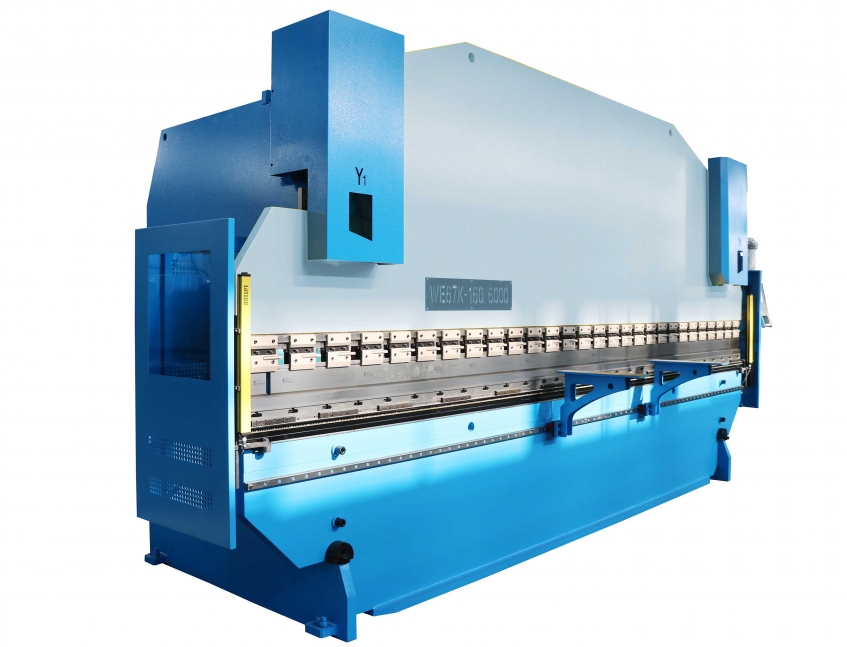

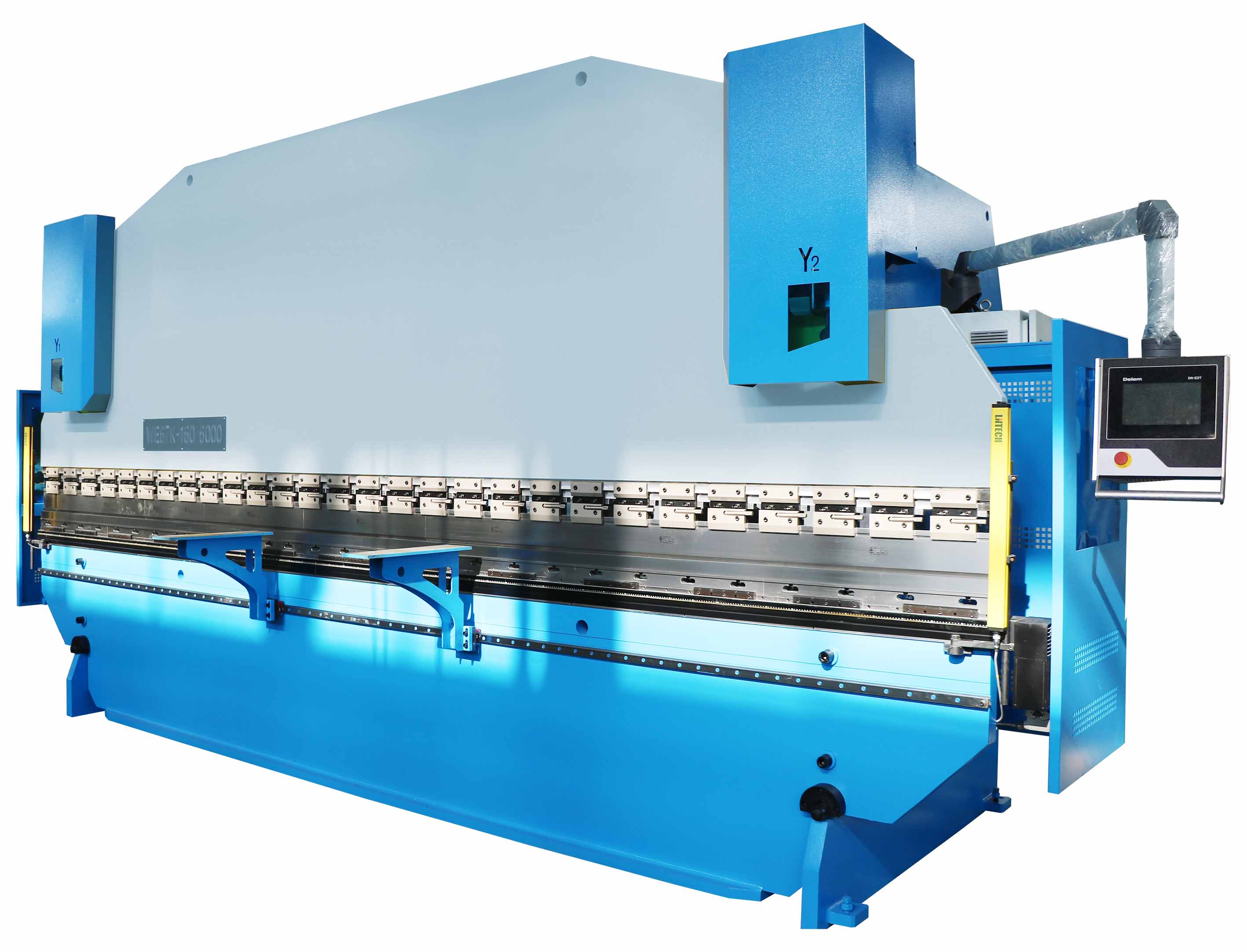

WE67K-160T6000 CNC Press Brake

Features

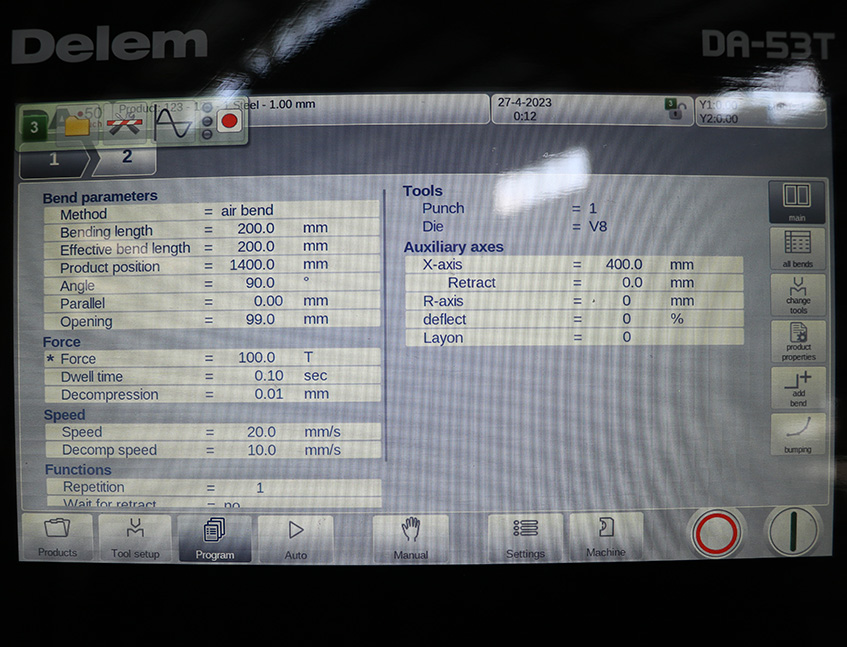

-- Y1-Y2-X-R +V axis CNC controlled

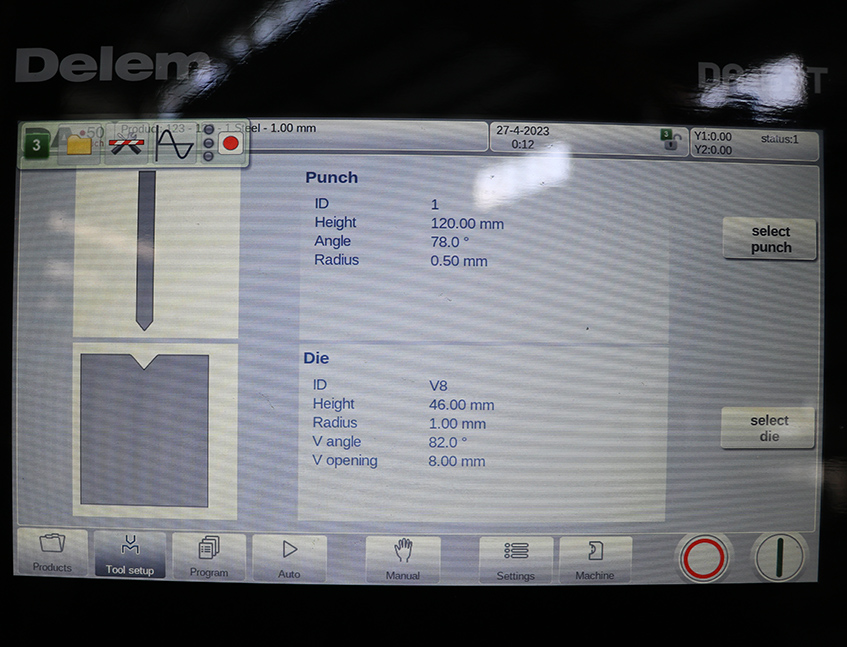

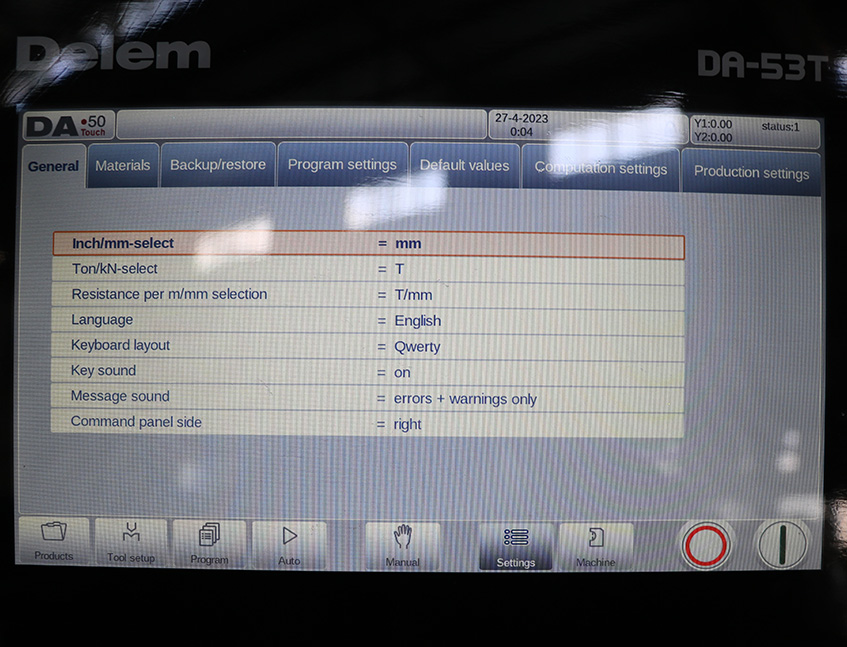

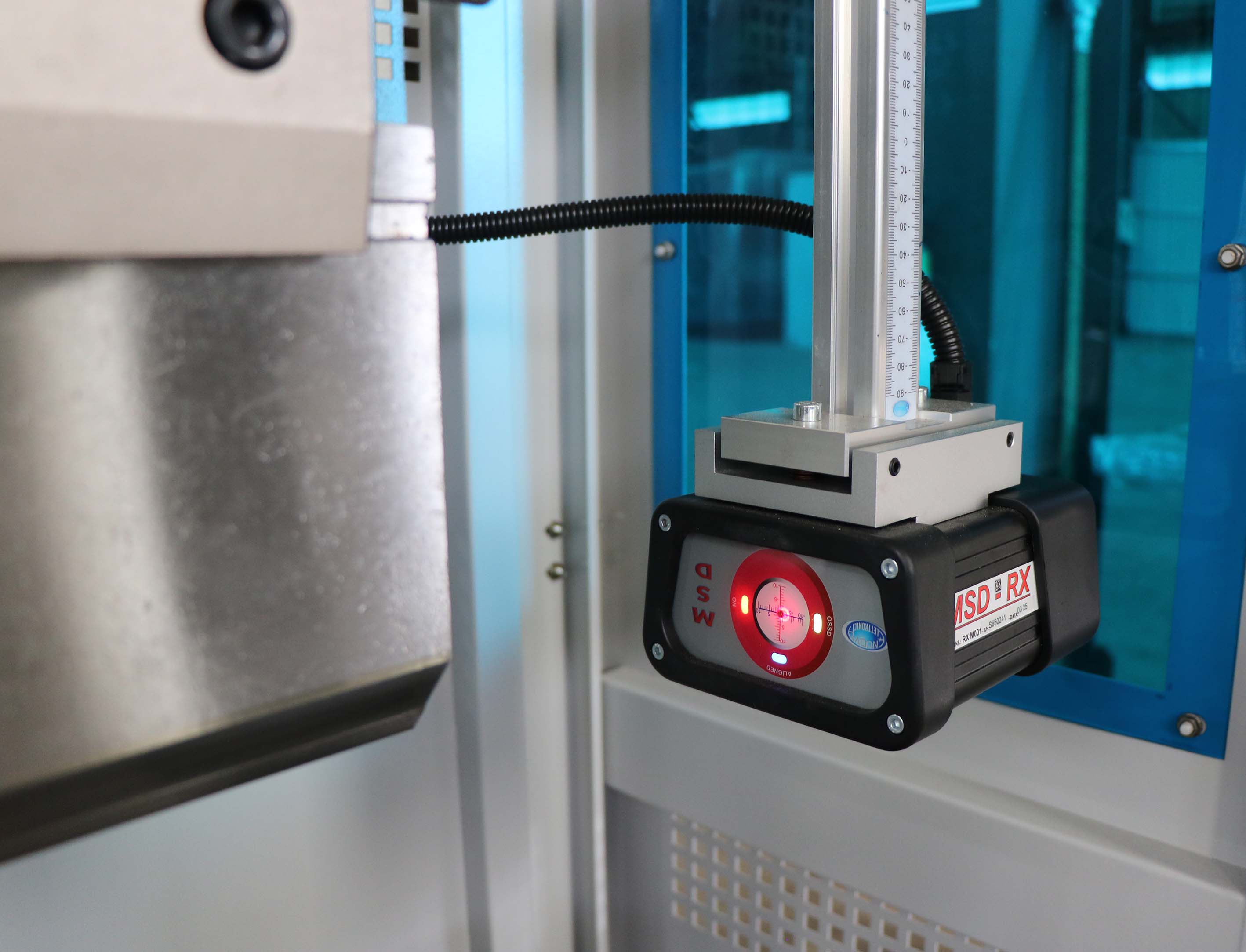

--DA-53T CNC system

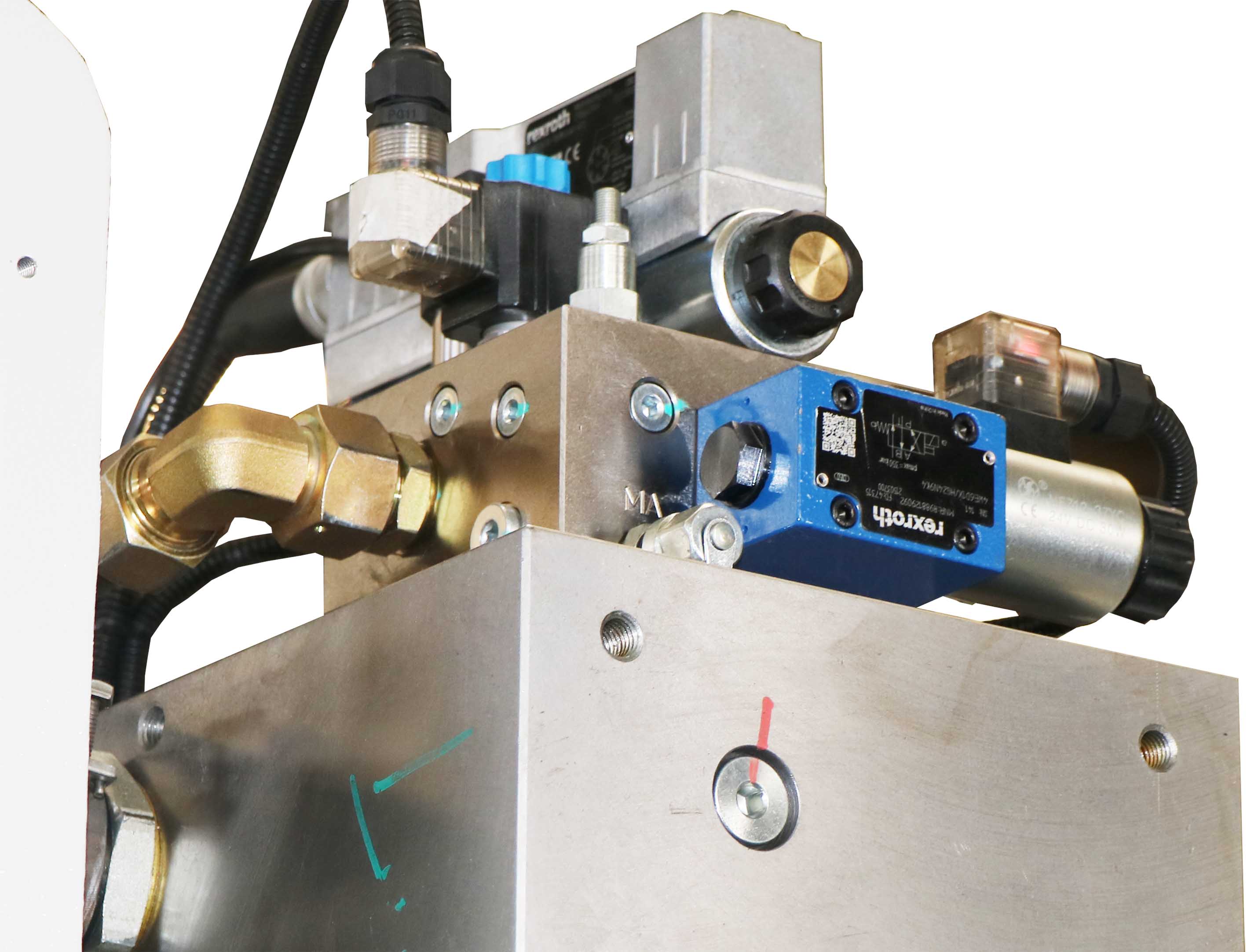

-- Close loop proportional hydraulics for beam synchronization

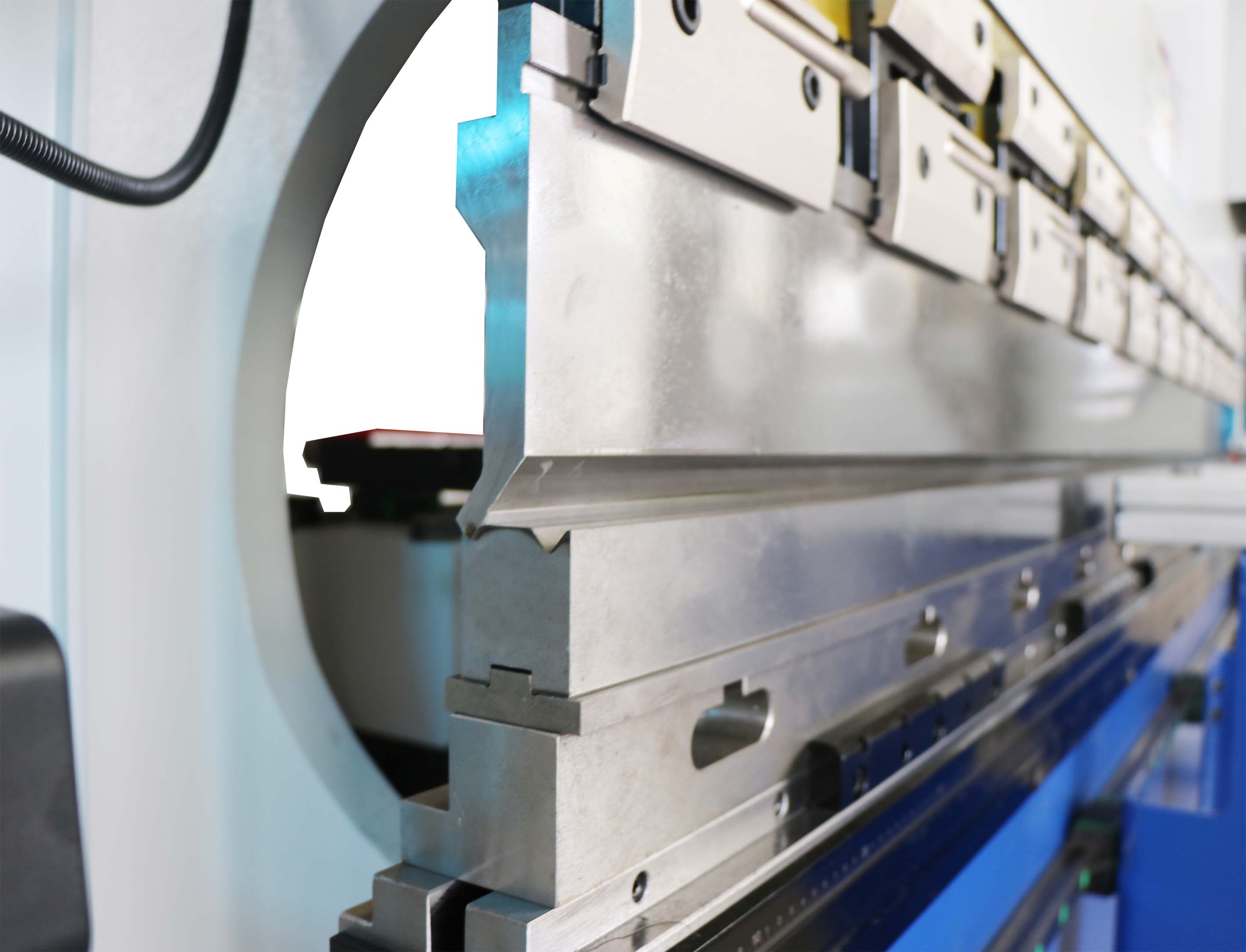

-- Hardened multi-V Die & Punch

-- Quick release die clamps

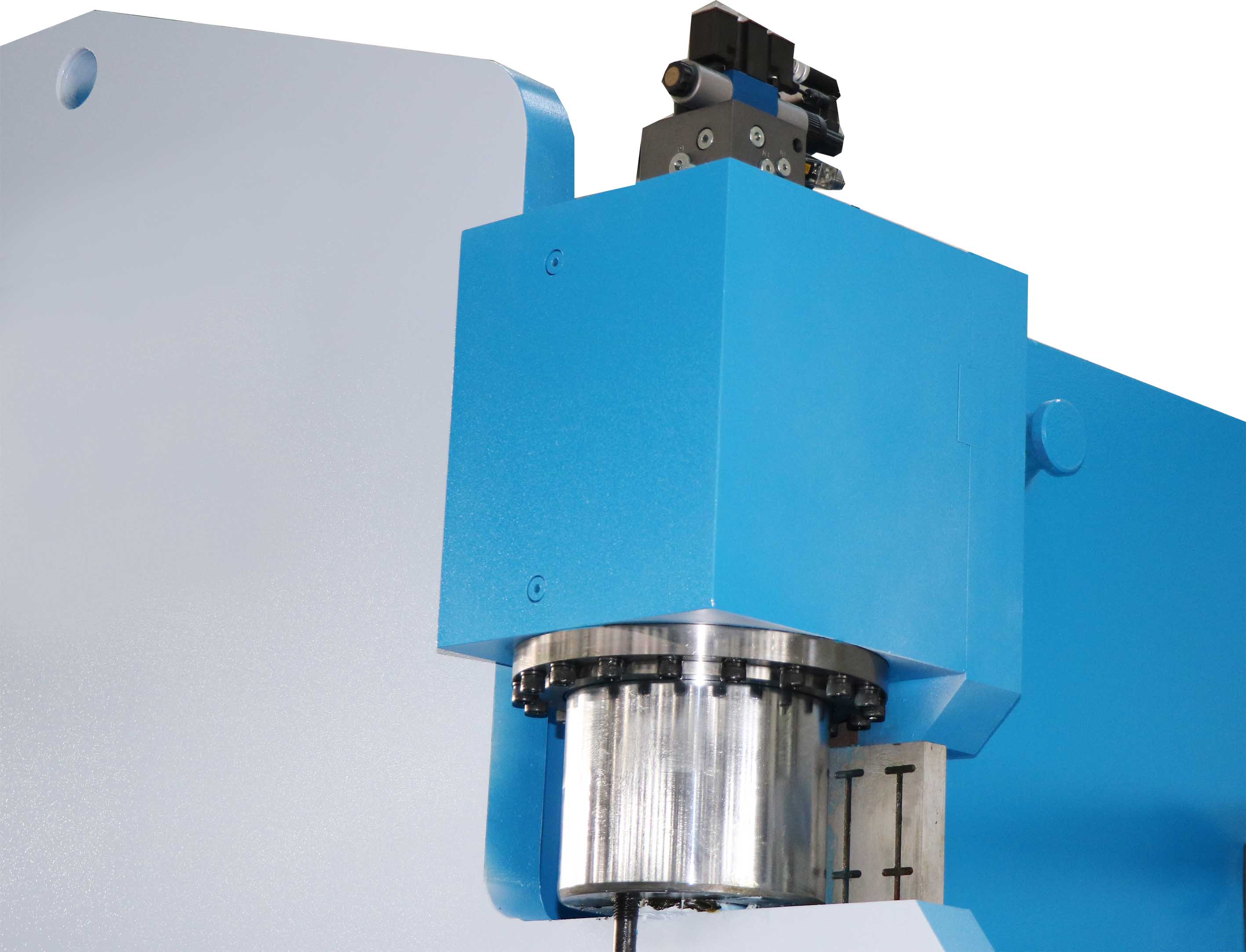

-- REXROTH precise proportional valve to control accurate beam movement

-- X-R back gauge consist of hardened & ground ball screw

-- liner motion bearings and AC servo drive for accurate position

Parameters:

|

1 |

Nominal pressure |

1600 |

KN |

|

|

|

2 |

Bending width |

6000 |

mm |

|

|

|

3 |

Distance between uprights |

4800 |

mm |

|

|

|

4 |

Stroke |

200 |

mm |

|

|

|

5 |

Max. Daylight |

470 |

mm |

|

|

|

6 |

Throat depth |

500 |

mm |

|

|

|

7 |

Working table length |

6000 |

mm |

|

|

|

8 |

Approaching speed |

110 |

mm/s |

|

|

|

9 |

Bending speed |

10 |

mm/s |

|

|

|

10 |

Returning speed |

90 |

mm/s |

|

|

|

11 |

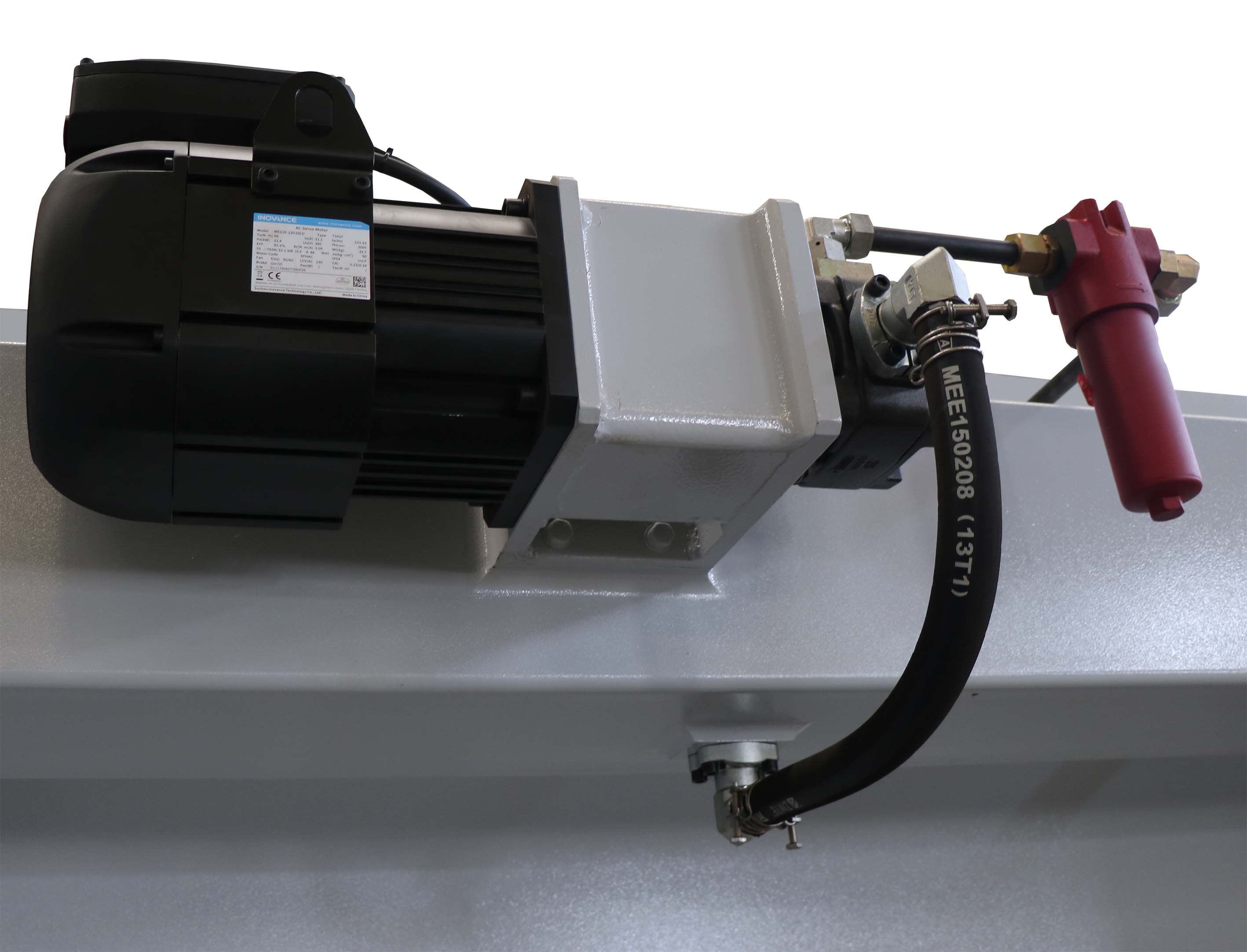

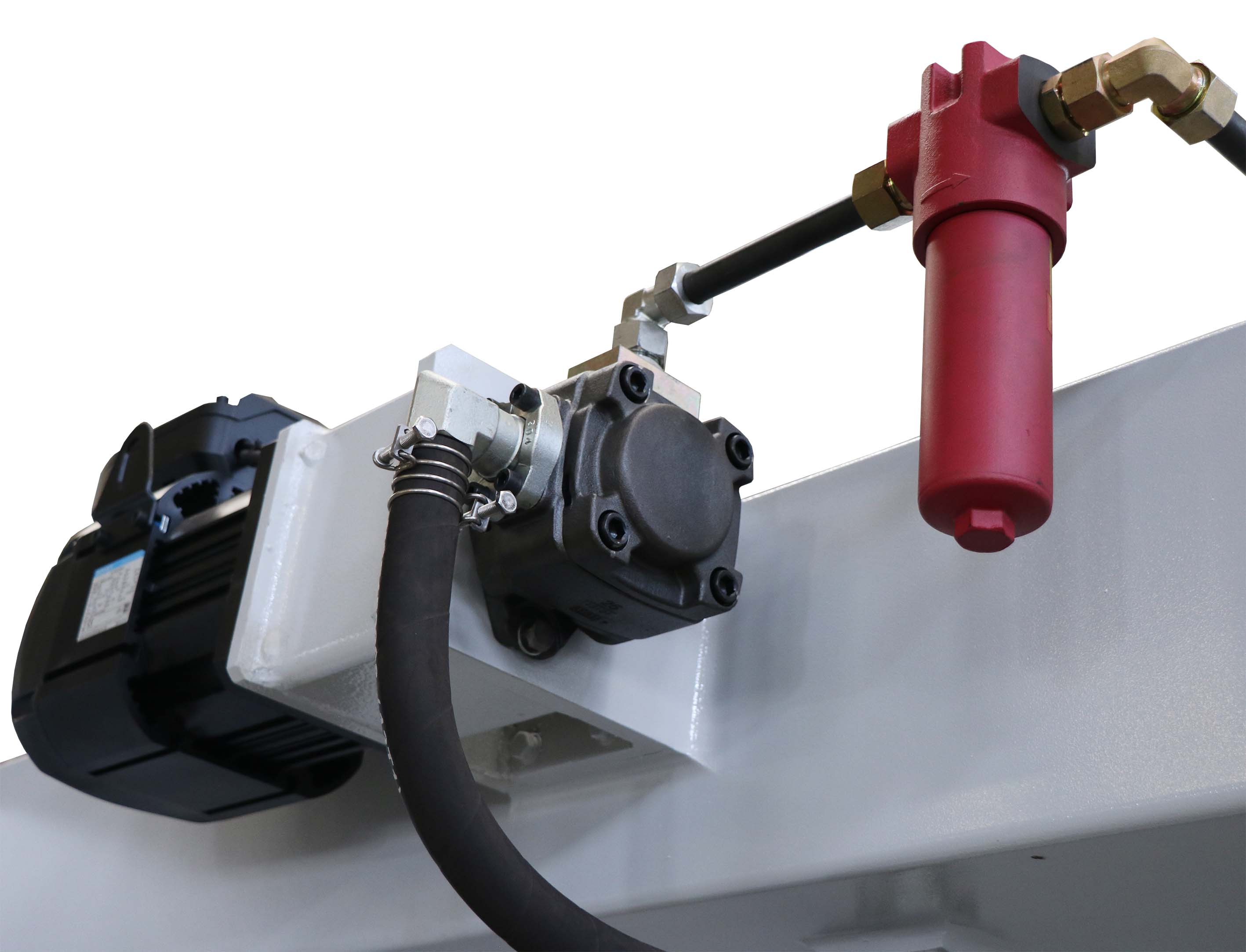

Main motor power |

11 |

KW |

|

|

|

12 |

Oil pump |

25 |

mr/r |

|

|

|

13 |

Back gauge range |

X range |

600 |

mm |

|

|

X speed |

450 |

mm/s |

|

||

|

R range |

200 |

mm |

optional |

||

|

R speed |

75 |

mm/s |

optional |

||

|

14 |

Machine length |

6300 |

mm |

|

|

|

15 |

Machine width |

1950 |

mm |

Without front feeder |

|

|

16 |

Machine height |

3050 |

mm |

|

|

|

17 |

axis |

Y1-Y2-X-R+V |

CNC |

||

Y1.Y2. axis re-position: ≤+0.05mm

Y1.Y2. axis position: ≤+0.03mm

X axis re-position: ≤+0.02mm

X axis position: ≤+ 0.05mm

Test bending angle: + 1°/3000 mm

Test straightness: ±0.75/1000 mm