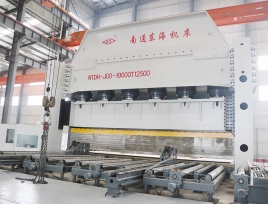

- JCO Pipe Forming Press

- Press Brake

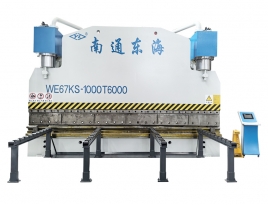

- CNC Press Brake

- Heavy Duty Press Brake

- NC Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- CNC Servo Press Brake

- Corrugation Press Brake

- Pipe Cutting Machine

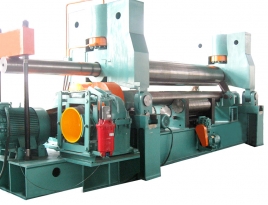

- Plate Bending Machine

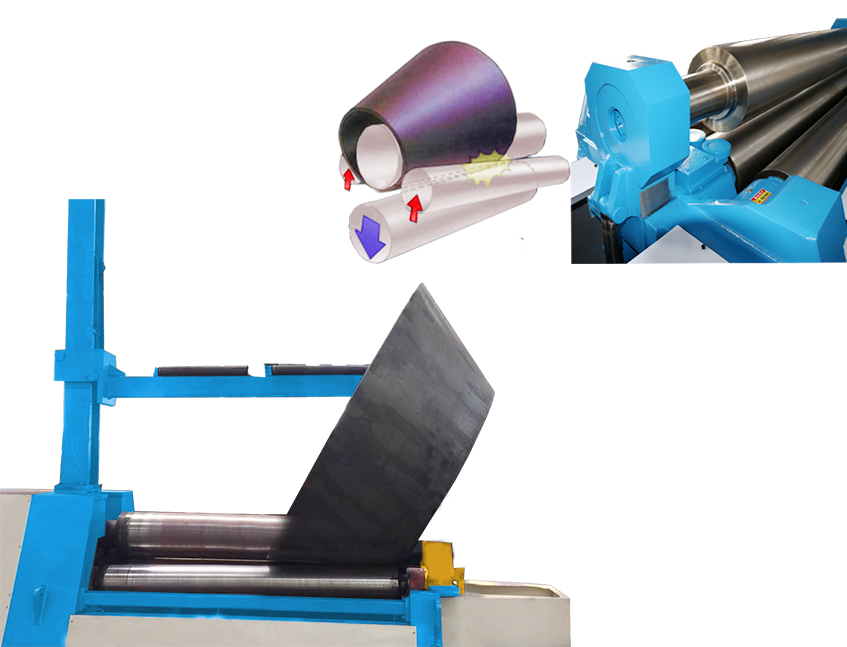

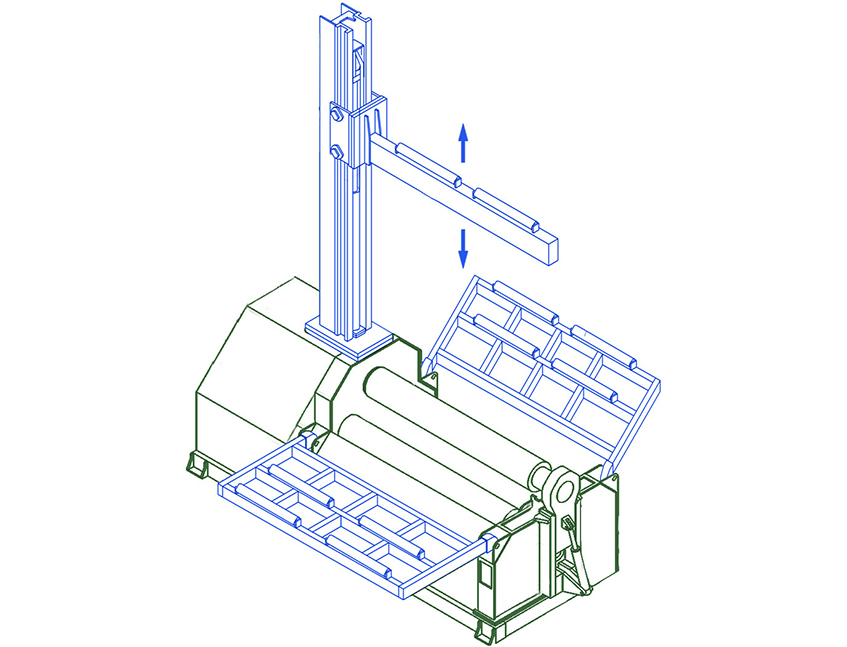

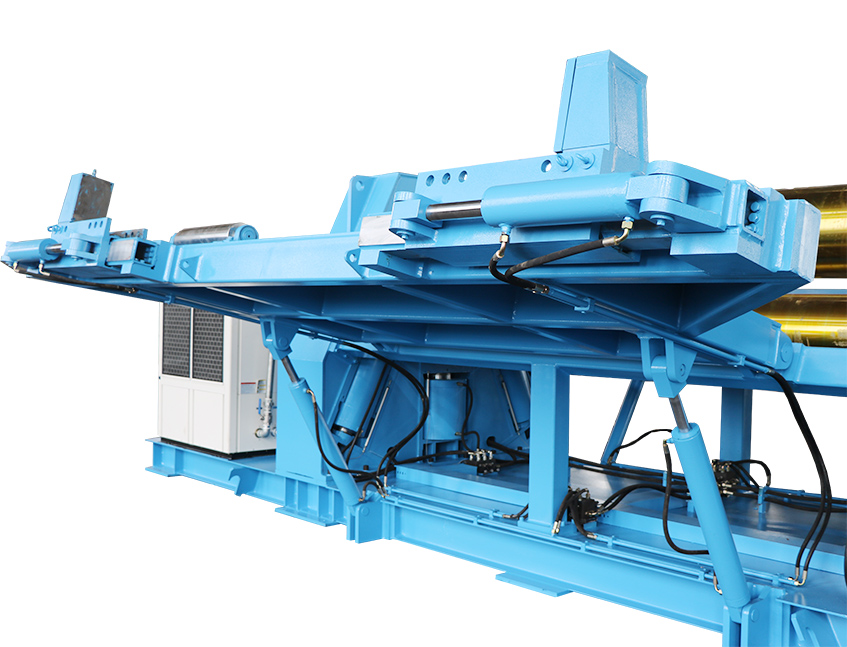

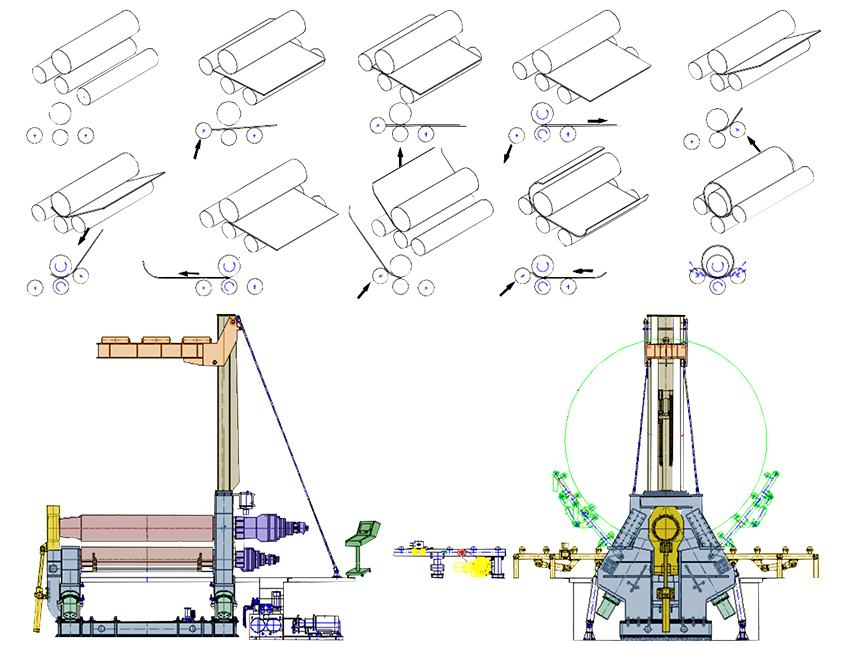

- 4-rollers Plate Bending Machine

- 3-rollers Hydraulic Plate Bending Machine

- 3-rollers Mechanical Plate Bending Machine

- 3-rollers Long Plate Bending Machine

- 3-rollers Asymmetric Plate Bending Machine

- 3-rollers Variable Geometry Plate Bending Machine

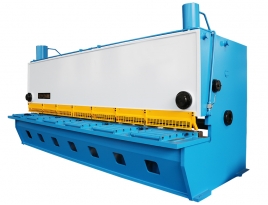

- Shearing Machine

- Guillotine Shearing Machine

- Swing Beam Shearing Machine

- CNC Shearing Machine

- Heavy Duty Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Cutting & Welding Line

- Offshore Double-End Cutting Machine

- Tube Cutting Machine

- Large Pipe Cutting Machine

- Pipe Cutting Machine

- H-beam Processing line

- H-beam Assembling-Welding-Straightening Machine

- H-beam Horizontal-type Flange Plate Straightening Machine

- H-beam Gantry-type Welding Machine

- U-Rib Assembling Machine

- H-beam Flange Plate Straightening Machine

- U-Rib External Welding Machine

- H-beam Horizontal-type Assembling Machine

- T-beam Assembling & Welding Line

- Box-beam Assembling Machine

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Parameters

- Pictures

- You May Like

- Inquiry Now

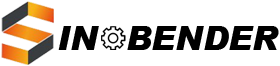

W12NC-80x3000 Four Rollers Plate Bending Machine

Parameters

|

Specification |

||||

|

Max. |

Thk. of bending plate |

(mm) |

80 |

|

|

Thk. of pre-bending |

65 |

|||

|

Width of bending plate |

3000 |

|||

|

Effective length of the rollers |

(mm) |

3100 |

||

|

Yield Strength of Plate |

(MPa) |

235 |

||

|

Min. reel dia. with max.size |

(mm) |

2500 |

||

|

Diameter of Roller |

Upper |

(mm) |

780 |

|

|

Bottom |

740 |

|||

|

Side |

650 |

|||

|

Roller |

Material |

42CrMo |

||

|

Hardness |

(HB) |

240-286 |

||

|

Induction Hardened Roll |

YES |

|||

|

Roll Profile |

crown |

|||

|

Lifting Mode |

hydraulic |

|||

|

Lifting Synchronous Precise/Accuracy |

±(mm) |

0.2 |

||

|

All Bearing Brand |

Self aligning roller bearing |

|||

|

Conical Bending Device |

Optional |

|||

|

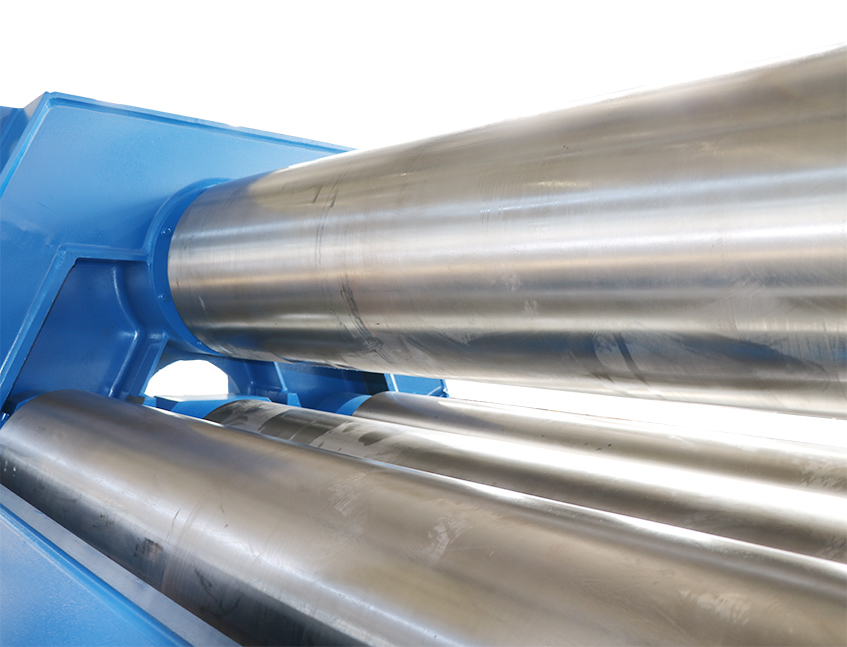

Driving Mode |

Hydraulic motor |

|||

|

Control System |

Control Mode |

CNC |

||

|

Display of position & displacement |

LCD |

|||

|

PLC |

ALIEN S650 |

|||

|

Electrical Part System |

ABB/SIEMNENS |

|||

|

Plate Bending Speed |

(m/min) |

about 3.5 |

||

|

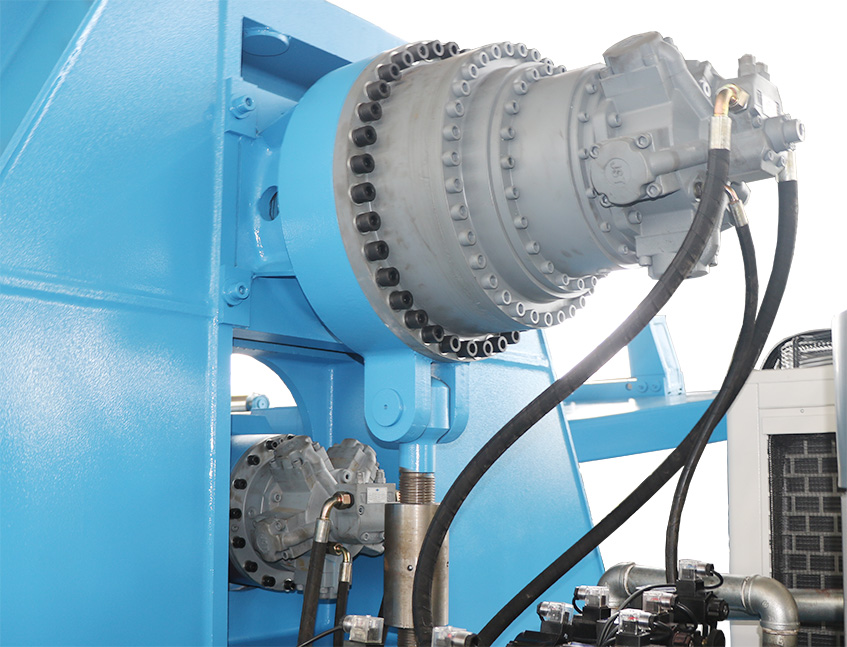

Hydraulic System |

Max. Working Pressure |

(MPa) |

31.5 |

|

|

Valve |

SOFIMA/YUKEN |

|||

|

Seal |

VALQUE |

|||

|

Electrical & Hydraulic Protection Againts Overload |

YES |

|||

|

Construction Steel Material |

Q235 |

|||

|

Side Support for Big Sheet Metal Diameters |

optional |

|||

|

Central Support for Big sheet Metal Diameters |

optional |

|||

|

Feeding Table |

optional |

|||

|

Oil Cooler System |

optiona |

|||

Features:

--heady duty linear sliding guides mounted on the uprights of the machine for lower roller and side rollers translation

--electronic parallelism control system

--rollers synchronization and balancing control fully electronically controlled

--side rollers and bottom rollers variable tilting controlled, positive or negative

--conical facility

--rollers driving by independent hydraulic motors

--anti-friction material in sliding area

--instantaneous brake for rollers rotation for high safety

--reversal side hydraulic driving

--Mobile control panel station, with low voltage control

--Mobile control push-buttons, convenience for operator