- JCO Pipe Forming Press

- Press Brake

- CNC Press Brake

- Heavy Duty Press Brake

- NC Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- CNC Servo Press Brake

- Corrugation Press Brake

- Pipe Cutting Machine

- Plate Bending Machine

- 4-rollers Plate Bending Machine

- 3-rollers Hydraulic Plate Bending Machine

- 3-rollers Mechanical Plate Bending Machine

- 3-rollers Long Plate Bending Machine

- 3-rollers Asymmetric Plate Bending Machine

- 3-rollers Variable Geometry Plate Bending Machine

- Shearing Machine

- Guillotine Shearing Machine

- Swing Beam Shearing Machine

- CNC Shearing Machine

- Heavy Duty Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Cutting & Welding Line

- Offshore Double-End Cutting Machine

- Tube Cutting Machine

- Large Pipe Cutting Machine

- Pipe Cutting Machine

- H-beam Processing line

- H-beam Assembling-Welding-Straightening Machine

- H-beam Horizontal-type Flange Plate Straightening Machine

- H-beam Gantry-type Welding Machine

- U-Rib Assembling Machine

- H-beam Flange Plate Straightening Machine

- U-Rib External Welding Machine

- H-beam Horizontal-type Assembling Machine

- T-beam Assembling & Welding Line

- Box-beam Assembling Machine

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Parameters

- Pictures

- You May Like

- Inquiry Now

WE67KM- 110/2500 CNC Servo Press brake

Parameters

|

Model |

Rated Force (mm) |

Bending Length (mm) |

Distance of Uprights (mm) |

Daylight (mm) |

Throat Depth (mm) |

Beam Stroke (mm) |

Motor Power (KW) |

Dimenssions (L x W x H) |

|

WE67KM-110T2500 |

110T |

2500 |

2050 |

500 |

320 |

200 |

2X4.4 |

2800X1380X2460 |

Features

▲ 60%-70% energy consumption

▲ 30% oil consummation

▲ moving control panel with on/off controls, emergency push button &selector for inching,

▲ High alloy back gauge, with high rigidity in light heavy

▲ 3+1 axis

▲ CNC controlled mechanical pulling-rod anti-crowing device(V)

▲ GIVI linear scale to avoid the deflection bending

▲ MT15 CNC control system

▲ liner motion bearings and AC servo drive for accurate position up to 0.05 mm.

Instruction of structure

--Stainless oil tanker + servo motor

The servo motor doesn’t rotate when the press brake does not work; The servo motor is rotating during the bending and returning period, and the energy consumption is 60%-70% compare to the traditional press brake.

--CNC control system

The control system is MT15 CNC control system, touch screen, 2D or 3D graphic.

--CNC crowning system

The mechanical wedge crowning device is placing under the lower die, using professional reducer and precision potentiometer to control the accuracy.

The mechanical wedge crowning device is placing under the lower die, using professional reducer and precision potentiometer to control the accuracy.

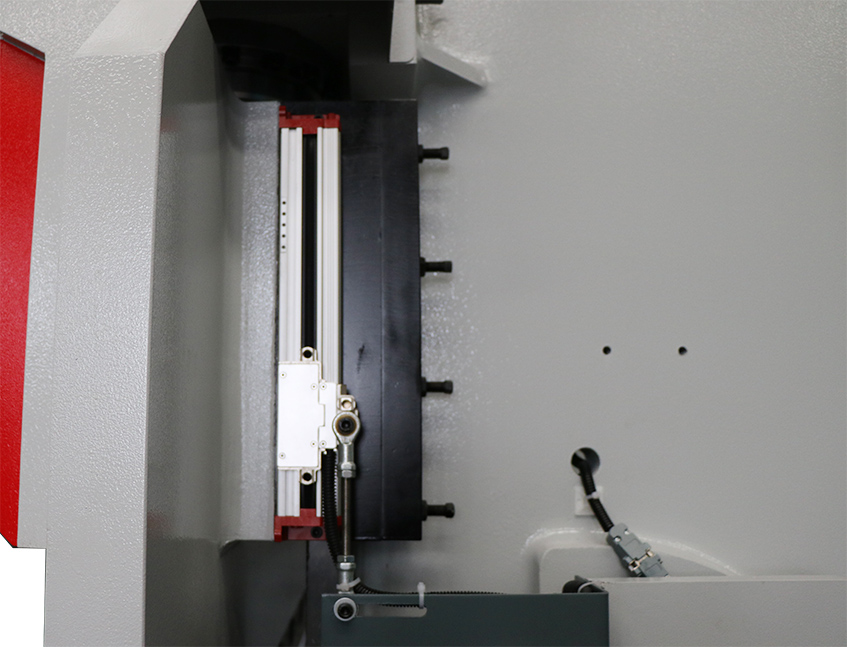

-- X back gauge

The back gauge is equipped with ball screw and linear rail. Manual adjust R axis.

The back gauge is equipped with ball screw and linear rail. Manual adjust R axis.

The functions of the back gauge can be extended up to 6 axis ((X1,X2,R1,R2,Z1,Z2).

-- Linear scale

Two pieces of linear scale were installed at the uprights to supply the reliable position and re-position accuracy.

-- Quick clamping system

Quick clamping system,the operator can change the tool through our quick clamping system.

Quick clamping system,the operator can change the tool through our quick clamping system.

--Moveable support

The front sheet support can move against the linear rail, fast and reliable.

The front sheet support can move against the linear rail, fast and reliable.

--Tool

#CNC, #pressbrake, #CNCpressbrake,#hydrid, #servopump,#servomotor