- JCO Pipe Forming Press

- Press Brake

- CNC Press Brake

- Heavy Duty Press Brake

- NC Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- CNC Servo Press Brake

- Corrugation Press Brake

- Pipe Cutting Machine

- Plate Bending Machine

- 4-rollers Plate Bending Machine

- 3-rollers Hydraulic Plate Bending Machine

- 3-rollers Mechanical Plate Bending Machine

- 3-rollers Long Plate Bending Machine

- 3-rollers Asymmetric Plate Bending Machine

- 3-rollers Variable Geometry Plate Bending Machine

- Shearing Machine

- Guillotine Shearing Machine

- Swing Beam Shearing Machine

- CNC Shearing Machine

- Heavy Duty Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Cutting & Welding Line

- Offshore Double-End Cutting Machine

- Tube Cutting Machine

- Large Pipe Cutting Machine

- Pipe Cutting Machine

- H-beam Processing line

- H-beam Assembling-Welding-Straightening Machine

- H-beam Horizontal-type Flange Plate Straightening Machine

- H-beam Gantry-type Welding Machine

- U-Rib Assembling Machine

- H-beam Flange Plate Straightening Machine

- U-Rib External Welding Machine

- H-beam Horizontal-type Assembling Machine

- T-beam Assembling & Welding Line

- Box-beam Assembling Machine

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Parameters

- Pictures

- You May Like

- Inquiry Now

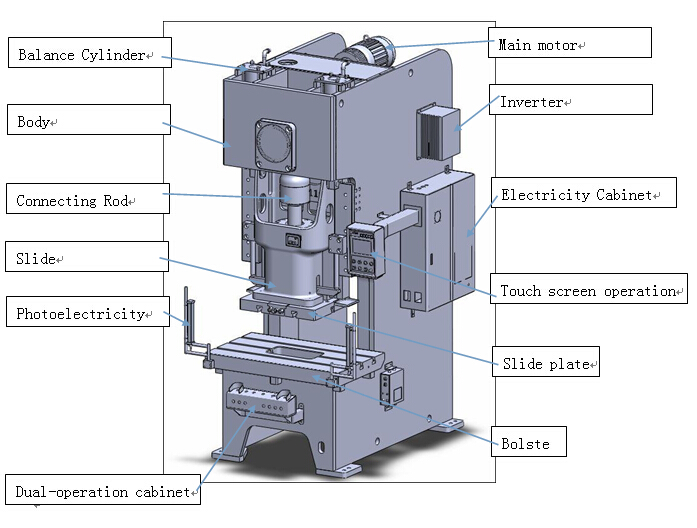

YC1 Series Single-crank Press Machine

--Main Structure Features

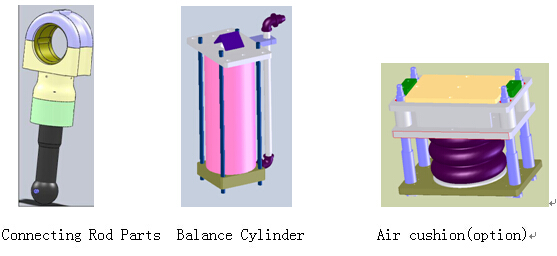

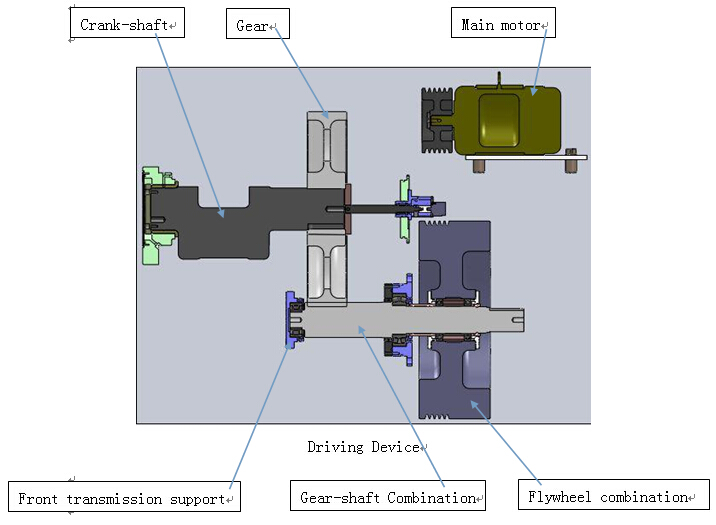

1.Main Structure:This series Press was composed of steel-welded frame, driving, clutch, brake, slide, air pipes, lubrication system, electrical system etc.. This structure was compact and good appearance.

2. Steel welded frame, with aging effect, can ensure the machine high rigidity and less deformation.

3.C-Frame structure, with steady precision, can improve the stamping precision and die serving life.

4. Longitudinal Crank Shaft, short distance between two supporting spot and high rigidity, compact and suitable structure. The gear drives in the oil, with low noise and less abrasive.

5. Pneumatic dry combination friction clutch-brake, mechanical interlock, security and credibility, good stability, low noise and long serving life.

6. Import hydraulic overload protection device, response rapid, working stability, outside oil tank, maintain easily.

7. Six-side long rectangle guides of the slide with high moving precision and high accuracy.

8. Automatic grease lubrication, with Progressive Grease Distributor and alarm system, was controlled by PLC system.

9. Automatic die adjustment device, digital monitor display, high precision achieve +0.1mm.

10.PLC electrical control system allow various auto-equipment reprogrammed according to different requirements and perform various functions, to ensure high reliability and high adaptability. Emergent stop,I nching, single and continuous movement.

11.Three connection parts of air system adopt SMC brand.

Specification

| Model | YC1-25 | YC1-45 | YC1-60 | YC1-80 | YC1-110 | YC1-125 | YC1-160 | YC1-200 | YC1-250 | |||||||||||

| V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | |||

| Nominal pressure | KN | 250 | 450 | 600 | 800 | 1100 | 1250 | 1600 | 2000 | 2500 | ||||||||||

| Nominal pressure stroke | mm | 3.2 | 2.3 | 3.2 | 2.3 | 4 | 2.3 | 5 | 3.2 | 5 | 3.2 | 5 | 3.2 | 6 | 4 | 6 | 4 | 6 | 4 | |

| Slide stroke | mm | 80 | 30 | 110 | 50 | 130 | 50 | 150 | 60 | 180 | 70 | 180 | 70 | 200 | 80 | 200 | 100 | 250 | 100 | |

| Strokes | Varible | S.P.M | 70-110 | 95-190 | 50-95 | 85-175 | 40-85 | 80-160 | 40-75 | 70-140 | 30-60 | 60-120 | 30-60 | 60-120 | 25-55 | 50-100 | 20-50 | 45-80 | 20-45 | 40-70 |

| Fixed | S.P.M | 75 | 135 | 65 | 125 | 60 | 120 | 60 | 100 | 50 | 90 | 50 | 90 | 45 | 80 | 35 | 60 | 30 | 55 | |

| Max. die set height | mm | 230 | 255 | 270 | 300 | 300 | 340 | 330 | 375 | 350 | 405 | 370 | 425 | 400 | 460 | 450 | 500 | 450 | 525 | |

| Die height adjustment | mm | 50 | 60 | 70 | 80 | 90 | 90 | 100 | 110 | 120 | ||||||||||

| Throat depth | mm | 170 | 230 | 270 | 310 | 350 | 370 | 390 | 420 | 430 | ||||||||||

| Slider area | LxWxT | mm | 350x300x50 | 430x350x60 | 500x400x70 | 560x460x70 | 650x520x80 | 700x560x80 | 700x580x90 | 850x650x90 | 920x700x100 | |||||||||

| Bolster area | LxwxT | mm | 720x320x70 | 850x440x80 | 900x520x90 | 1000x600x100 | 1150x680x110 | 1200x720x120 | 1260x760x140 | 1400x820x160 | 1550x840x180 | |||||||||

| Hole for punch shank | Diameter | mm | Φ38.1 | Φ38.1 | Φ50 | Φ50 | Φ50 | Φ50 | Φ65 | Φ65 | Φ65 | |||||||||

| Main motor powr | KW xP | 3x4 | 4x4 | 4x4 | 5.5x4 | 7.5x4 | 11x4 | 15x4 | 15x4 | 18.5x4 | ||||||||||

| Slider adjusting device | KW xP | manual | manual | 0.3x4 | 0.4x4 | 0.75x4 | 0.75x4 | 1.1x4 | 1.1x4 | 1.1x4 | ||||||||||

| Air pressure | kg/cm3 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | ||||||||||

| Height of bolster surface | mm | 800 | 800 | 800 | 830 | 845 | 845 | 1020 | 1020 | 1120 | ||||||||||

| Capacity of die cushion | Ton | / | 2.6 | 3.6 | 6.3 | 8 | 8 | 10 | 10 | 14 | ||||||||||

| Stroke of die cushion | mm | / | 60 | 70 | 70 | 80 | 80 | 100 | 100 | 100 | ||||||||||

| Effective are of die cushion | mm | / | 300x250 | 350x300 | 450x310 | 500x350 | 500x350 | 660x460 | 660x460 | 660x460 | ||||||||||

| Overall dimensions | F-B | mm | 832 | 860 | 970 | 1180 | 1305 | 1385 | 1575 | 1575 | 1740 | |||||||||

| L-R | mm | 1060 | 1350 | 1390 | 1755 | 1935 | 2010 | 2300 | 2300 | 2345 | ||||||||||

| Height | mm | 2165 | 2375 | 2585 | 2685 | 2915 | 3020 | 3675 | 3675 | 4000 | ||||||||||

| Weight | Kg | 1900 | 3700 | 5400 | 6300 | 9500 | 10500 | 14200 | 19000 | 26000 | ||||||||||