- JCO Pipe Forming Press

- Press Brake

- CNC Press Brake

- Heavy Duty Press Brake

- NC Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- CNC Servo Press Brake

- Corrugation Press Brake

- Plate Bending Machine

- 4-rollers Plate Bending Machine

- 3-rollers Hydraulic Plate Bending Machine

- 3-rollers Mechanical Plate Bending Machine

- 3-rollers Long Plate Bending Machine

- 3-rollers Asymmetric Plate Bending Machine

- 3-rollers Variable Geometry Plate Bending Machine

- Shearing Machine

- Guillotine Shearing Machine

- Swing Beam Shearing Machine

- CNC Shearing Machine

- Heavy Duty Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Cutting & Welding Line

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Parameters

- Pictures

- You May Like

- Inquiry Now

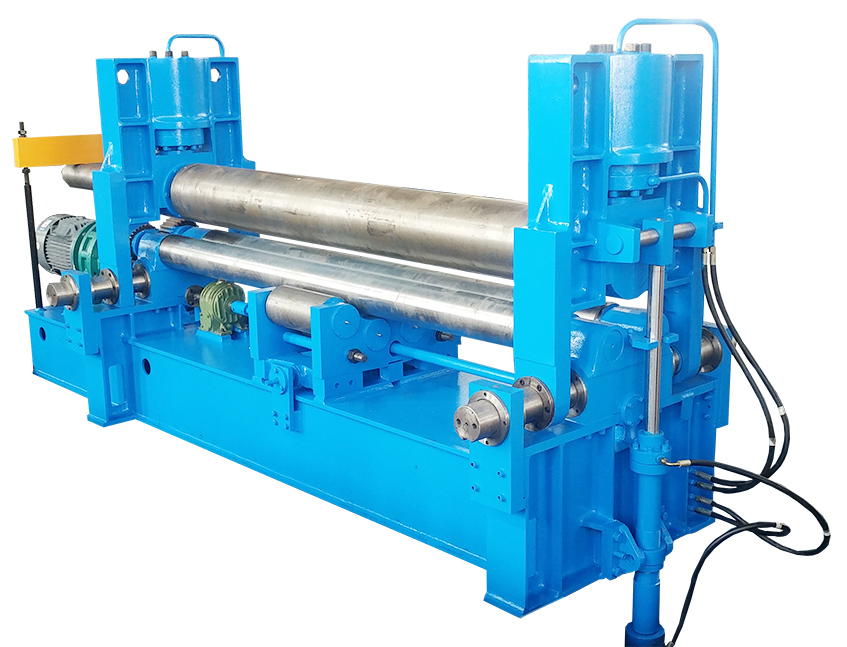

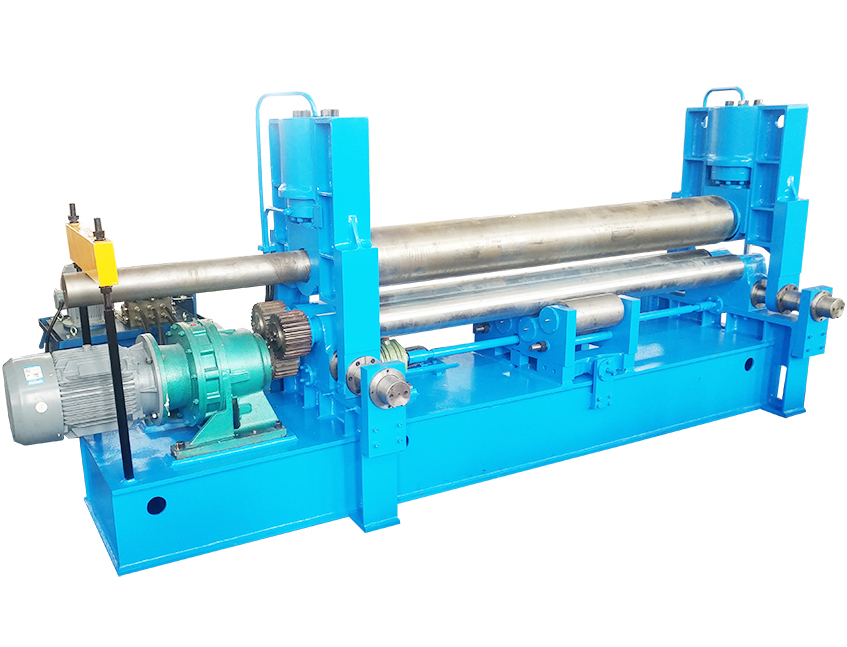

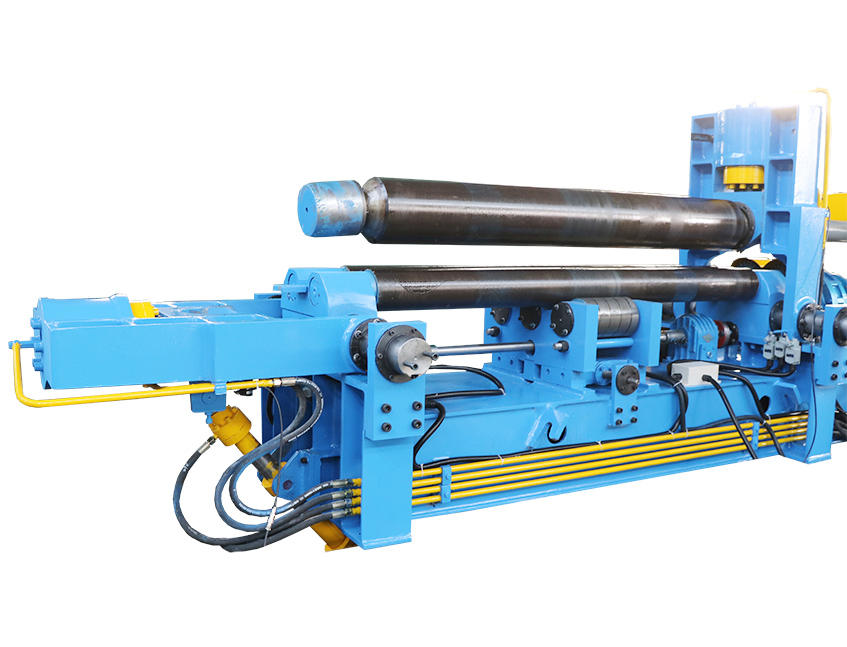

W11SNC-12x2000 Plate Bending Machine

|

W11SNC-12x2000 |

|||

|

Rated Pressing Force from Upper Roller |

Ton |

65 |

|

|

Working temperature |

At natural temperature |

||

|

Plate yield limit |

MPa |

245 |

|

|

Max. |

Thk. of bending plate |

(mm) |

12 |

|

Thk. of pre-bending |

10 |

||

|

Width of bending plate |

2000 |

||

|

Min. rolling dia. with max.size |

(mm) |

600 |

|

|

Diameter of Roller |

Upper |

mm |

250 |

|

Bottom |

mm |

145 |

|

|

Working Rollers |

Material |

42CrMo |

|

|

Hardness |

(HB) |

260-300 |

|

|

Induction Hardened Roll |

YES |

||

|

Roll Profile |

crown |

||

|

Lifting Mode |

hydraulic |

||

|

Central distance of bottom rollers |

mm |

200 |

|

|

Diameter of supporting roller |

mm |

145 |

|

|

Adjusting way of supporting rollers |

motorized |

||

|

Rolling speed |

m/min |

3.5 |

|

|

Power character |

380V/50Hz/3phase |

||

|

Control System |

Control way |

PLC control + moving controller |

|

|

Display of position & displacement |

LCD |

||

|

PLC |

OMRON |

||

|

Electrical Part System |

SIEMNENS |

||

|

Main Power Motor |

(KW) |

5.5 |

|

|

Motor for hydraulic |

(KW) |

4 |

|

|

Motor for horizontal moving |

(KW) |

0.75 |

|

|

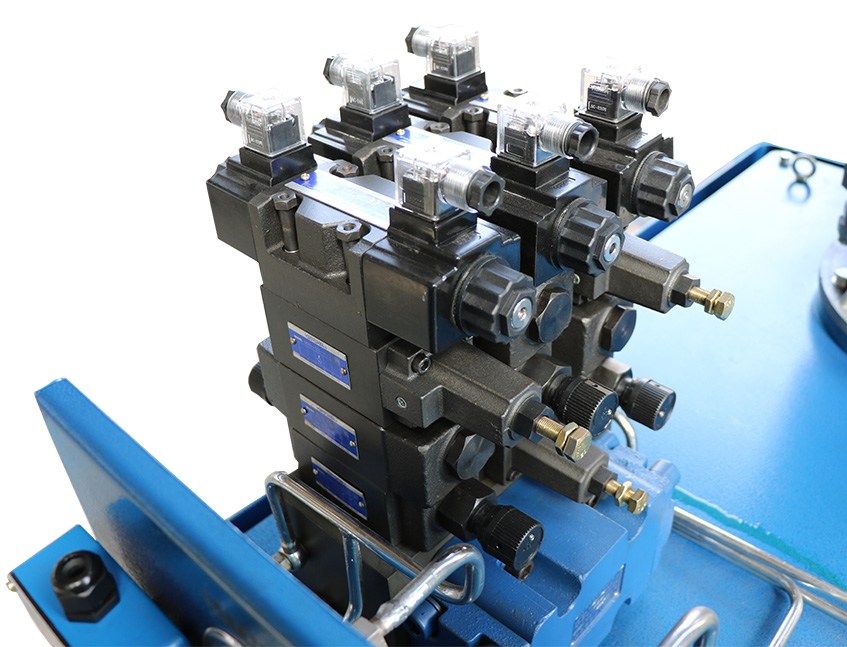

Hydraulic System |

Max. Working Pressure |

(MPa) |

19.5 |

|

Valve |

YUKEN |

||

|

Seal |

VALQUE |

||

|

Electrical & Hydraulic Protection Againts Overload |

YES |

||

|

Construction Steel Material |

Q235 |

||

|

Side Support for Big Sheet Metal Diameters |

optional |

||

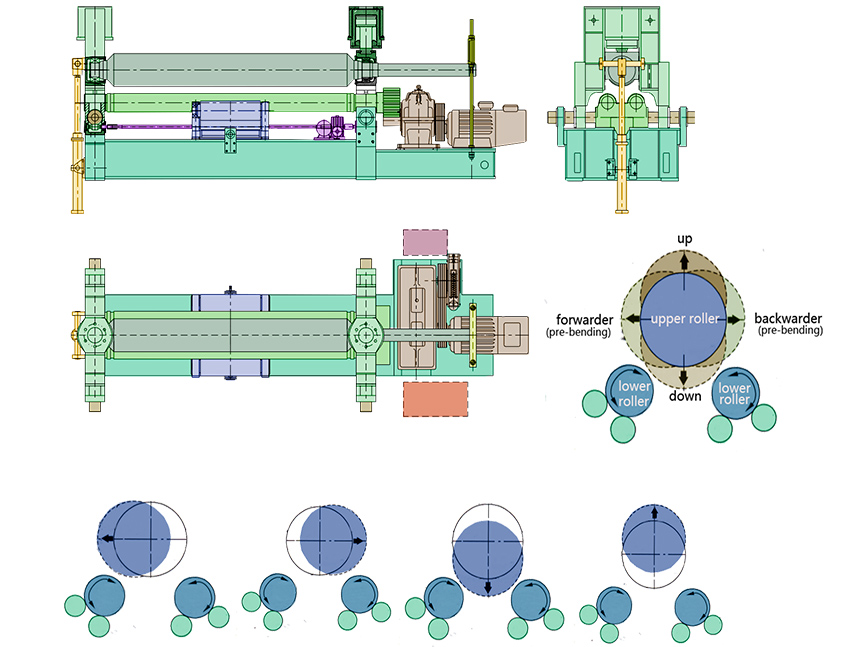

Features

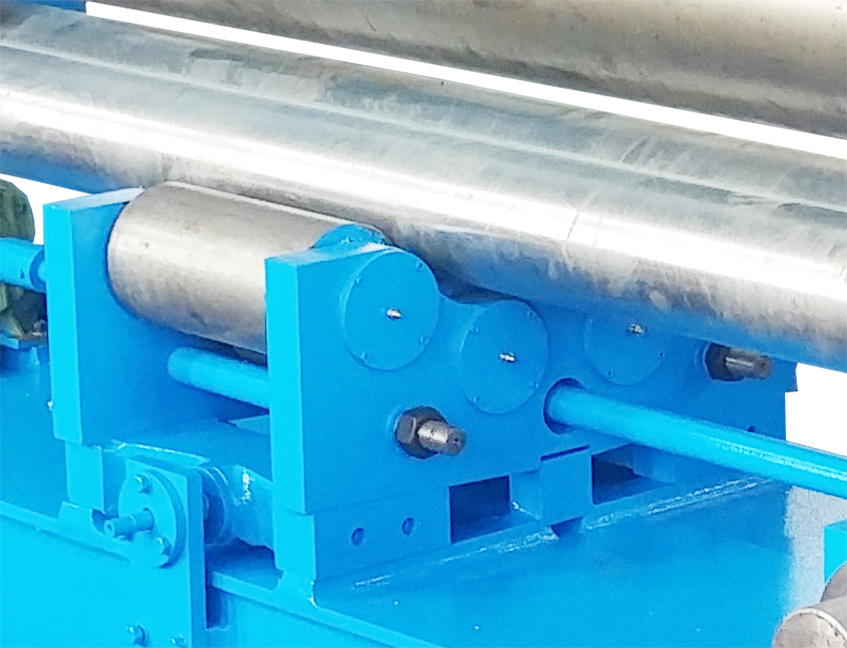

▲electronic parallelism control system

▲rollers synchronization and balancing control fully electronically controlled

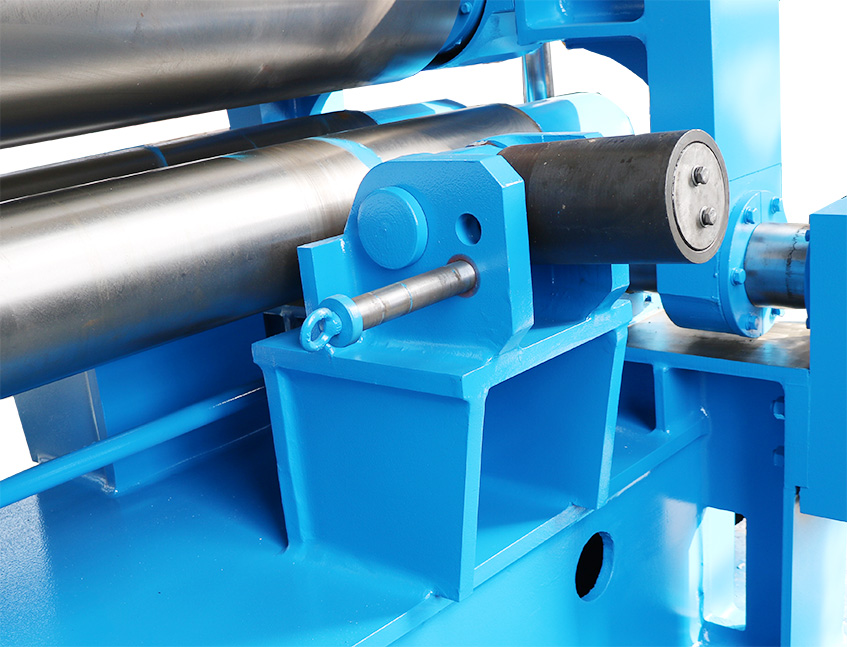

▲top roller hydraulic driving, can be vertically and horizontally adjustable.

▲anti-friction material in sliding area

▲instantaneous brake for rollers rotation for high safety

▲reversal side hydraulic driving

▲Mobile control panel station, with low voltage control

▲Mobile control push-buttons, convenience for operator

plate bending machine, rolling bending machine, plate rolling machine, hydraulic bending machine, roll bender, rolling machine